I would like to take the time to present an idea I have come up with.

Please note that I am a layman when it comes to the field of rocketry so please keep this in mind

My idea is " The usage of a ferromagnetic fluid, such as ferrofluid, as a replacement of conventional rocket fuel in order to develop a rocket engine which would have the potential of recycling its fuel continuously through the usage of motor pump technology. All the while containing both the rocket along with the fuel and other components of the engine inside of a casing so that the different fluids do not escape from there respective housings.

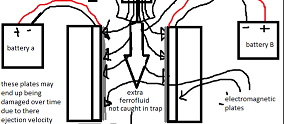

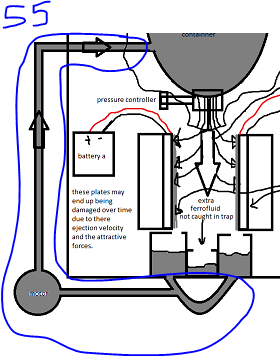

(Here is a general image of the idea that I am proposing)

(I apologize for this being done in paint, I will try and improve upon the visuals of the design at a later point in time)

I would like to now take the time to explain this systems functions for how it would complete the objective described in the beginning statement.

I will be highlighting each section on how they work and how they interact with one another.

Section(1)

Section 1 Is the large fuel tank which would hold both a ferro fluid along with the highly compressible material. The highly compressible material would generate a pressure on the surface of the ferrofluid causing it to have a tendency toward the bottom of the container. Section 1 is also where the ferrofluid is recycled into along the highly compressible material.

Section 2

Section 2 is the pressure controller and the ferrofluid outlet. Ferrofluid would be ejected at a controlled rate out of this nozzle using the pressure controller. This is what would cause the rocket engine to propel itself upward, that being the rocket nozzle, in a controllable manner.

Section 3

Section 3 is the ferrofluid capture environment. This is where the ejected ferrofluid would be captured by a strong magnetic field generated by electromagnetic "plates". (Please note that I am using the term plates as a placeholder for a material that would capture the ferrofluid) Each "plate" would be charged by separate electronic sources. Any non captured ferro fluid would be let out into the next section. After the ferrofluid has been captured it would then "fall off" into section 4 due to the demagnetization of the electromagnetic plates.

Section 4

Section 4 is a ferrofluid collection environment where the ferrofluid will drop off into after it has been demagnetized. After this it would then be drawn into up into section 5.

Section 5

Section 5 is the ferro fluid recycler. Where the ferrofluid would be recycled back into section 1.

Section 6

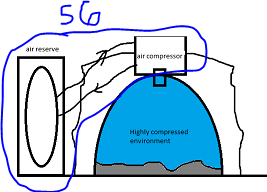

And finally section 6 is the back and forth highly compressible material storage and compressor. It interacts with section 1 by refilling it with highly compressible material.

Problems I have run into when trying to flush out this idea

> The magnetic field used to collect the ferrofluid would have to be strong enough in order to overcome the high velocities of the ejected ferrofluid.

> The magnetic field used to collect the ferrofluid would have to be weak enough so that it does not impede the ejection process of the ferrofluid

> Constant usage of the ferrofluid may cause nanoscale damage to the ejection nozzle and the motor pumps over time due to well metal scraping metal.

> The compression rate of the highly compressible material would need to match the refill rate of the ferrofluid into the section 1.

> The "falling off" rate of the ferro fluid would need to be fast enough that the ejected ferro fluid is constantly being attracted to the electromagnetic plates.

> probably billions more problems

Thank you for taking the time to read over this.