Everything posted by Enthalpy

-

Hear Conical Brass Instruments

gtmusicalinstruments has a better page to listen the cornetto, there gtmusicalinstruments with more music on this instrument.

-

COVID-19 antivirals and vaccines (Megathread)

Strange, don't lie to favour your misconceptions.

-

String Instruments

I had suggested it on January 27, 2019 07:39 PM and followings scienceforums and the ancient Chinese Konghou harp has already soundboards parallel to the strings. How loud is the Konghou? It seems to work very well. Hear the exquisite sound XqT7nfXTp5c I like immediately this music from the opposite side of Earth. Because a harp carries it? The low notes sound deep, better than the Erard-style harp Pc2mD5vAhww - E1aUfdLSi64 - 04oWysYCN0o - Gv0DOFkhFm4 - UbYA_K9QoWc that's what I expected from the bigger and more flexible soundboard. Introduction: the instrument abandoned for centuries was revived and modernized around 1980 QReFNf4RzAM 7 notes * 5 octaves, right and left identical. Double-movement pedals identical to the Erard design. Erard-system harpists can play the Konghou immediately 1oO_oCAlWxM - ZuUrtGTfWoM so European and US luthiers should make harps with vertical soundboard before all musicians prefer the Konghou. Equalling the range of the concert harp is a matter of resistance and stiffness, and the tall Konghou soundbox helps, while the neck can be taller at the centre. Steel gains a bit over wood. I had proposed a single-strung instrument instead. Stress halved, and the harpist sees better, but the soundboard is shallower at high notes. The Konghou's bridges stress the soundboard far less than the Erard-style does. My proposal to imitate the piano or to pull at the board's end injects no side force at all. This enables a lighter and louder soundboard.

-

COVID-19 antivirals and vaccines (Megathread)

Experts are seldom thrilled by suggestions made by outsiders, but outsiders bring most progress. Yes, ideas are badly scarce,. And on the Internet, you find the same people as in companies, with the same skills but not as grossly misused. Think at the Steinway. The production of fullerenes or graphene. The chipcard. The contactless chipcard. Many solutions for the Fukushima disaster. Paypal. SpaceX. Tesla. And so on and so forth. Waiting for experts, or worse for known experts, to solve everything and bring all innovation is a recipe for stagnation. It's also contrary to observation.

-

COVID-19 antivirals and vaccines (Megathread)

One step better, IF silver destroys the Covid virus efficiently: Deposit a silver film directly on the handle or the item. Solutions exist for that. The surface acts as a catalyst, and it doesn't have to be metallic. Easier than copper, mechanically safer. Primers or treatments may be useful, or not, to let the silver layer adhere on varied materials. Handles are often coated with some unreactive polymer. Degreasing is a minimum, maybe sanding a little bit with quite fine paper. Silver handles could be useful in hospitals for instance. Marc Schaefer, aka Enthalpy

-

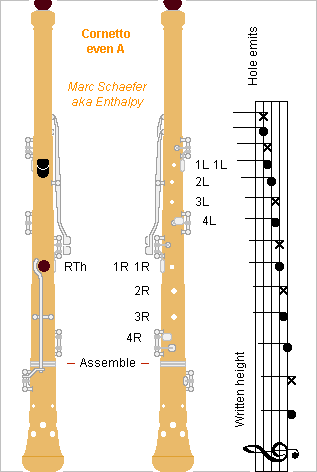

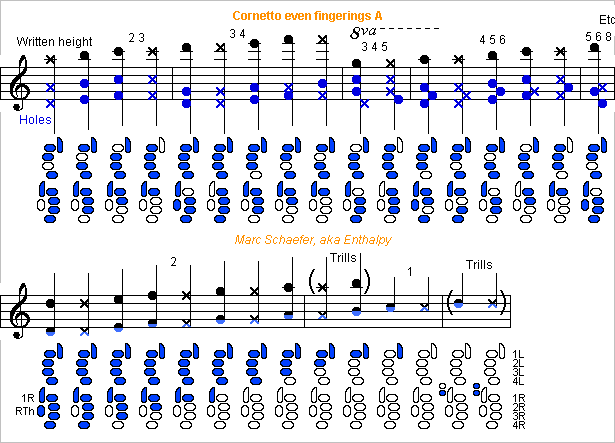

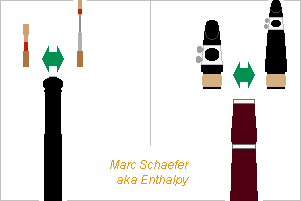

Woodwind Fingerings

Brass instruments with side holes are played quite rarely: cornetto = zink = cornett, serpent, ophicleide scienceforums - scienceforums Their mellow sound seems strong and has no equivalent among modern instruments. Excepted for the ophicleide, their fingerings and (lack of) keyworks are said to resemble a recorder, which hampers good tuning. Recorder fingerings also use to make timbre and ease of playing uneven, but this isn't patent on the records. So shall they get my even fingerings? They bring holes all open below the main transition, with regular spacing and diameters. Here my oboe even fingerings D scienceforums - scienceforums are slightly adapted, becoming the cornetto even fingerings A, where many bare holes give an antique look. Here I suppose that the lowest note can octaviate properly, then one thumb key suffices, with two throat trill keys like the clarinet has. These fingerings are mere indications that the scheme is flexible enough to enable high modes evenly. The fingerings will evolve if the instrument is built and tried. For instance if the tone holes are a semitone higher than the pressure node, this holds for the main transition, but isolated holes tend to sit at the pressure node. All fingerings can drift upwards or downwards, though compatibility with my oboe system would be nice. I've drawn no register keys, do they help a labrophone? I'd keep the cornetto's bore width, important for the sound and range. Sideholes about as narrow are all-important too. If the lowest side holes are narrow for good sound, then the instrument should have Stowasser's small holes before the bell, as depicted above. Chambers at the tone holes can remove the strident component of the grain if needed, split holes remain efficient at low instruments scienceforums - scienceforums ========== Regular hole spacing is expected to ease high registers by using isolated open holes, and low brass are known for their huge range. So should the cornetto family get my automatic fingerings? scienceforums - scienceforums and next They play a big range much more easily but lose the simple keys and antique look. ========== The cornetto made a family with varied sizes, the serpent being a bass. When modernizing, it's tempting to create two instruments per octave, shaped like the sarrusophones for instance, rather in C and F. Though, the ability to play old scores is very important. I would not keep the serpent's hole positions. Regular spacing is important, keys enable that. Hole diameters shall bring a consistent timbre in the family, not imitate the serpent. ========== Old instruments were probably of BuxusSempervirens, still excellent for small parts and looking antique. Dalbergia melanoxylon outperforms it but is endangered. Liquid crystal polymer would outperform both with graphite choppers, or maybe pure if stretched during injection or extrusion. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

I suggested liquid crystal polymer (LCP) for wind instrumens body and more parts. Graphite choppers increase E=11GPa to E=23GPa, exceeding Dalbergia melanoxylon. But cutting tools may wear out faster. LCP is known to stiffen quickly and strongly along the injection direction. Often undesired in injected parts, this effect gives LCP fibres E=270GPa, and would improve a body made from extruded or injected raw material. Instruments accept a transverse stiffness somewhat lower, so adjustment room is available. Stretched LCP could then be stiffer and denser than Dalbergia melanoxylon but spare the cutting tools. Marc Schaefer, aka Enthalpy

-

COVID-19 antivirals and vaccines (Megathread)

The friend sent me pictures of copper tape on the doorhandle: The sheet's edges are a weak point of the construction. They might hurt the user or accumulate dirt and viruses at the concave angles, spoiling the benefits of copper. That reason favours the broad copper tape over my proposed helical winding of narrow tape. Rounded corners would stay glued on the handle and be less dangerous. Maybe solder would secure the edges and fill the concave angles. I'd also flatten the edges by pressing with a hard round tool, maybe a light hammer, before sticking and soldering, and sand after soldering. It's not investigated against Covid, but usually silver sterilizes better than copper does. Solutions exist to deposit it on copper by immersion.

-

COVID-19 antivirals and vaccines (Megathread)

Hi everybody! As I read many people using hypochlorite ("bleach") as a disinfectant against Covid-19, I should like to remind that hypochlorite is dangerous. It's the one chemical that kills most people in household accidents. Percarbonate is a disinfectant too, bur not treacherous like hypochlorite. Where I live, it is sold as 0.5kg powder buckets. Odours and tensides are often added, alas. Use it dilute in water or as a watery paste to disinfect items suspect of contamination.

-

COVID-19 antivirals and vaccines (Megathread)

Hello everybody! A new study is available on medrxiv prior to peer-review and publication https://www.medrxiv.org/content/10.1101/2020.03.09.20033217v2.full.pdf it tells that Covid-19 "lives" shorter on a surface of copper than of stainless steel, cardboard or polymer. Silver was not tested. A friend of mines proposes and will try to cover doorknobs with copper tape in collective houses. If the quite thin copper foil doesn't hurt the hand, this seems a good idea. https://en.wikipedia.org/wiki/Copper_tape I suppose the intricate shape takes narrow tape to cover, where individual layers are loose but two overlapping layers cover the knob completely. The copper tape would end where hands don't touch if possible, and be covered by usual adhesive tape there. All retail is closed here, but copper tape exists at Web sellers, as long as deliveries work.

-

Hear Conical Brass Instruments

An other musician playing the cornetto nicely, there: gtmusicalinstruments.com search "project Suzanne", from 2:30 to 6:10 approximately that's a damn nice instrument, and different from what we have now. Whether it can be modernized in a clever way: make it easier, improve the tune, but keep the sound?

-

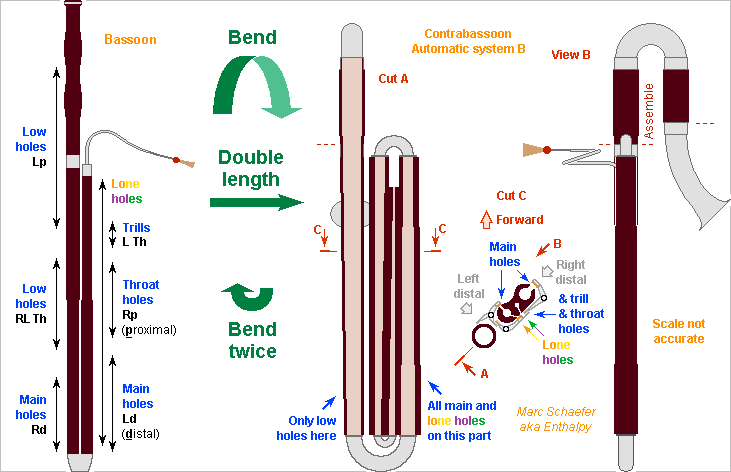

Woodwind Fingerings

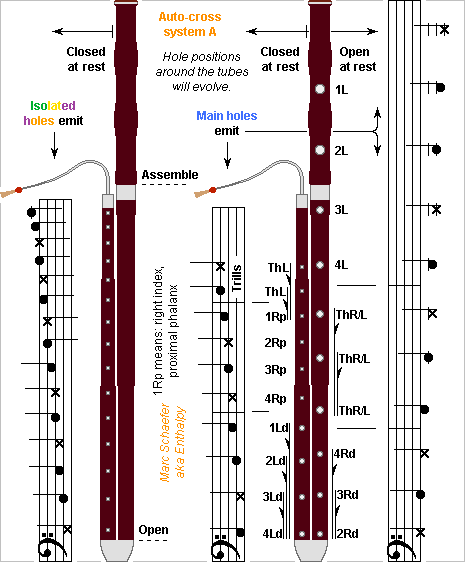

Basing on the basson's automatic system B, here's a contrabassoon aspect. The fingerings were described here in 2020 on Jan 18, the lone holes on Jan 19, the other holes on Jan 26 scienceforums - scienceforums - scienceforums and the automatic system B keeps the bassoon's aspect of system A of Jan 12 scienceforums which the contrabassoon bases on, as on the following sketch. The bassoon's aspect eases the keywork. This contrabassoon's aspect keeps the lower bend (migrated at the top) and bends the narrow and wide joints near their middle to retain most advantages. The synchronized left hand's main holes are aligned on a single branch. The synchronized right hand's main holes, independent of the left hand's ones, are aligned on an other branch. The lone holes spread now on two branches, but they can emerge on lines close to an other, maybe on a single line. The thumbs' low holes spread on two branches now but are synchronized. Single known drawback. The throat holes and the left proximal low holes spread on several branches but they're independent. So the successive branches, seen on the cut A, hold these holes, starting from the bocal: Some lone holes. Trills. Some throat holes. The other lone holes. Left hand main holes. The other throat holes. Right hand main holes. Some thumb low holes. The other thumb low holes. Some left-hand low holes. Still ascending after the assembly, the but-last left-hand low hole. After the bend, the last left-hand low hole. Without the last bend, the orchestra's lowest wind is also the tallest, it resembles more a big bassoon, and its box becomes even smaller. Other foldings make sense too. The first branch can stop after the thoat holes, the longer second branch hold all main holes, the third all thumbs low holes aligned and some left hand low holes, the fourth the other left hand low holes without extending over the others. The assembled instrument is more compact but looks styleless and its case is longer. On a contrabasson, all bends can fit between side holes but be wide enough to sound well. The bend from branch 3 to 4 seems too long, but the scale isn't accurate, and the branch 4 can be out of the plane of branches 1, 2 and 3. ========== The branches sequence 3, 1, 2 can make a compact arrangement seen on the cut C. This enables the displayed lucky holes and keys arrangement where: All holes on branch 1 are at the rear, away from the condensation flow. Other branches use to be dry. The branch 3 some 45° before the branch 2 gives both hands a comfortable position. The lone holes on branches 1 and 2 can be treated identically. All right hand main holes have simple keys. The neighbour buttons for lone holes look the same, the keys for throat holes too. All left hand main holes have simple keys. The neighbour buttons for lone holes look the same. The lone holes' keys are distinct from their right and left buttons, but simple. Tiny extra complexity for a contrabassoon. The trill and left low holes keys seem simple too. Only the movements from right thumb to the three covers need extra thinking. Lone hole keys separate from the buttons give flexibility. The lone buttons could be away fom the palm at both hands. One button could open the 1:2 and 3:4 lone holes at once as on system A. Though, full compatibility with the bassoon is more important, and these options complexify the bassoon. Do they ease playing the bassoon? No, I don't want a basson built like this contrabassoon. I like the size and shape of the bassoon. ========== The cut C displays the branches 1, 2 and 3 bored in a single part. This makes more accurate and stable keyworks, saves assembly labour, reduces the size, brings stiffness expected to improve the sound at branch 1 - but it needs a wider part. Easy with polypropylene and polyketone, quite possible with Acer I suppose, doubtful for most Dalbergia, and I ignore the cost of LCP. Whether the branch 4 can and should belong to the same part? I had no mobile parts traversing the body. Soon inventing the rackett? ========== I've drawn a loop in the bocal whose orientation doesn't accumulate condensation water but leads it to the branch 1. If this is better, it applies also to my contrabasson with even fingerings of Dec 01, 2018 scienceforums ========== I've (re-) started learning the French bassoon, and I confirm that a better system is extremely welcome, be it my even one or my automatic one. From what I see on fingering charts, the Heckel system isn't radically easier to play. Marc Schaefer, aka Enthalpy

-

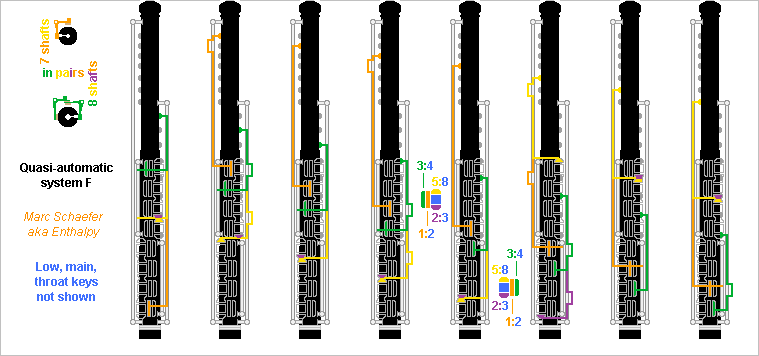

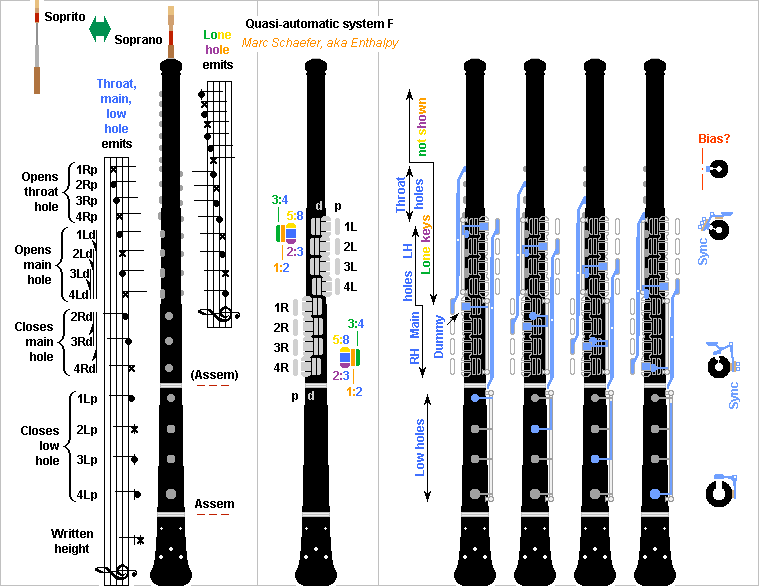

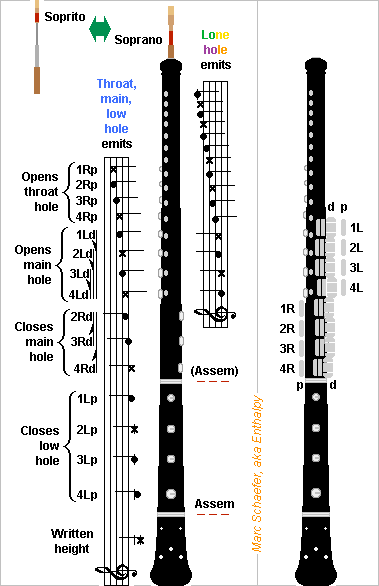

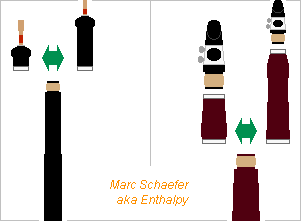

Woodwind Fingerings

The system E of Feb 09 and 16, 2020 here was really overcrowded, probably impracticable. Here a quasi-automatic system F for the oboe and similar. 8 lone holes are now at the left side, other holes moved a bit too. 7 lone hole shafts at the right and 8 at the left, as concentric pairs, are now hopefully manageable. The holes are wider apart too. I've also put at the left side the axle for the right hand main holes. 7 buttons no more on their lone hole key need a transmission. I also mirrored the buttons at the right hand, so the main button now closest to the palm and the 1:2 button are easier to catch without the now farthest 3:4. This is the only fingering difference with system E, so if I don't draw new ones, the fingerings of Feb 09, 2020 apply with mirrored right hand. The right hand three keys plus the dummy button can hold on a single axle like at the saxophone, with transmissions as proposed there scienceforums while the left hand has four complete keys, synchronized too. More accurate design shall tell where all shafts fit and in what sequence to mount them. The throat keys resemble a clarinet's trill keys. Convenience may let redesign the drawn vertical axis. The low keys too are drawn with a vertical axis, possibly improvable. Four independent movements must be transmitted to the low joint. Some parts not shown here let the musician close all low covers with one hand to assemble the joints. This system F looks as complex as the usual oboe, but at least all keys are banal, without the oboe's exotic parts prone to fail. It shall be easier to play and offer new possibilities. Marc Schaefer, aka Enthalpy

-

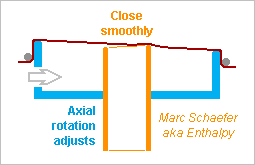

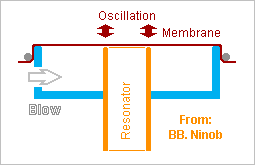

Music Instruments Parts

Upon suggestion by Jean-Paul Bosselut, BB. Ninob researched membrane reeds and instruments and published there la.trompette.free.fr (in French) Instead of cane, a membrane vibrates on a resonator. It lets air flow in when the pressure in the resonator is high to provide net alternating power from the steady feed. Adapted from the document: The membrane reed makes very strong sound of poor musical quality. Maybe the aperture was bigger than what fits the resonator: on a clarinet it's less than 1mm high when played, times 10mm width. A tube exceeds easily this perimeter. ========== I also have a strong intuition that the membrane shuts brutally and completely the aperture for a portion of the period. This creates unpleasant high harmonics, just like a saturating amplifier does. To make a pleasant sound, mouthpieces for single reeds have a carefully optimized curved slope to face the reed, which then closes the aperture smoothly. By similarity, I propose to shape the aperture so the membrane reed closes it smoothly. Just tilting the aperture versus the membrane would already do it. With luck and an aperture matching the resonator losses, the membrane reed might then also play piano like a clarinet does, and keep a decent sound at moderate strength. If the membrane support is tilted by as much and the support can rotate versus the aperture, this adjusts the inclination. The aperture's shape can be more elaborate. It can be curved and have several peaks and valleys. ========== Maybe the blowing pressure pushing also on the membrane's outer face would let the reed work over a wider pressure range. Or not. Marc Schaefer, aka Enthalpy

-

Woodwind Fingerings

At an oboe or similar, here are the positions of the holes and buttons for system E quasi-automatic cross-fingerings of Feb 09, 2020. The many shafts overcrowd an oboe much, a saxophone less so. The transverse position of the holes can still evolve. Marc Schaefer, aka Enthalpy

-

Woodwind Fingerings

As a variant of the Feb 09, 2020 message here, an oboe or similar could keep its upper part and swap its reed for a smaller one mounted on a bigger staple to stay tuned when doubling as a soprito. This saves hardware. The soprito staple can be longer, end narrower, and include a barrel(s), possibly a throat. By similarity, a smaller single reed would have a mouthpiece with bigger volume to use the instrument as a soprito. Though, the existing barrel may be inadequate then, and tuning details depend on the mouthpiece manufacturer. But does the tárogató already have a barrel? No detachable one can be seen. The instrument has a reputation of bad tune. Marc Schaefer, aka Enthalpy

-

Woodwind Fingerings

I suggested on Feb 09, 2020 a smaller reed and adapted instrument upper part to concentrate on high notes scienceforums I expect a bassoon with my quasi-automatic system B (here on Jan 18, 2020 and around) to resonate well on mode 12, so if reeds adequate for the lowest notes can't play that high, musicians could just raise the range by an octave with a smaller reed and a bocal that keeps the tune. Maybe a heckelphone reed, or just a shortened bassoon reed, snip snip. And, err, lone holes are accessible individually on my system B, just in case the mode 12 doesn't suffice. Bassoonists like to extend the instrument's range, carry bunches of bocals, and fiddle with the reeds all the time, so if my system B exists some day, luthiers should offer this option early. Marc Schaefer, aka Enthalpy

-

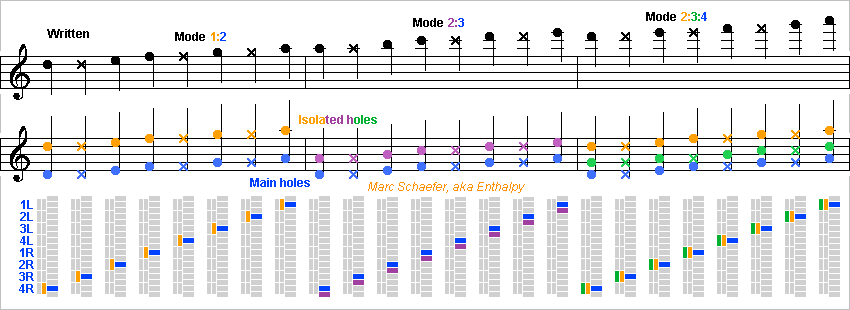

Woodwind Fingerings

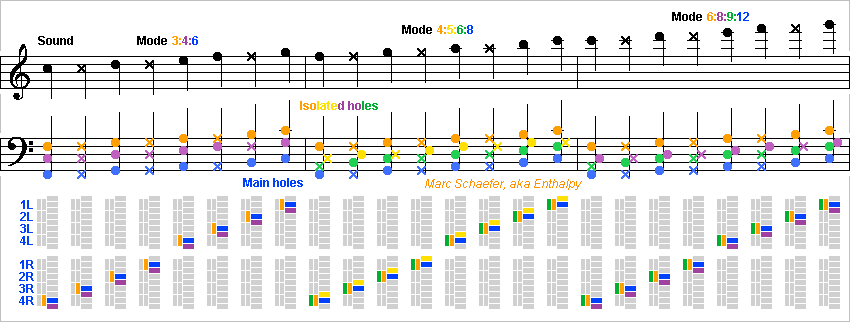

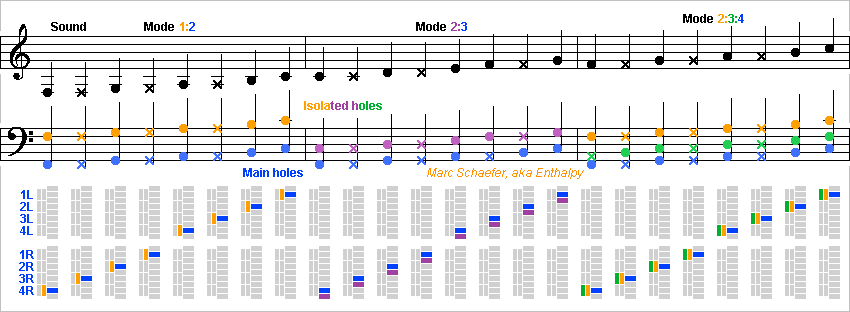

I've adapted the bassoon's quasi-automatic system B as the quasi-automatic system E for the oboe, saxophone and similar. It's not strikingly simple like the even fingerings system D scienceforums but it shall ease the high notes' emission and fingerings. The isolated holes are specialized hence optimized in size and loss, maybe split scienceforums and they reside up to the written A position to ease the high notes. Up to B seems accessible at an oboe or sopranino saxophone. The long fingerings and many opened isolated holes should make high notes better in tune and nicer at the high saxophones, tárogató, oboe. The tiny oboe's tone holes attenuate high components, but isolated holes improve the resonance at higher modes. Other (quasi-) automatic systems have isolated holes less high on the air column, they open no isolated hole in mode 2, are globally less capable, but still need three buttons around each main button scienceforums so the present one seems better despite its mode 12 is overkill for a soprano saxophone. I've put 4 low holes closed by 1L to 4L at the proximal phalanges. Then, the isolated holes reach A. The simple independent keys for low holes fit curved low saxophones more easily. The right hand is then just above its main holes, a semitone lower than usual, and the left hand over its main holes too, a bit lower than usual. The main and isolated holes are transposed from the bassoon's quasi-automatic system B, explanations there. 4 throat holes extend the mode 1 to reach mode 2. The right proximal phalanges shall open the independent keys. Maybe two low holes can make the trills between modes 1 and 2. Or have extra keys, say at 3L and 4L. The isolated holes should make register holes unnecessary. The thumbs are free if needed. Fingers 1 play also higher than fingers 4, so non-bassoonists should feel easy. ========== The oboe bore, narrower than a piccolo flute, can resonate strongly more than an octave beyond the usual range. Many efficient isolated holes could extend the soprano oboe to the soprito's range, fascinating possibility. scienceforums and around I doubt that one oboe reed covers that range, but the musician could swap a simple top part and reed on one oboe to play an octave higher. Maybe a less wide tárogató could also swap a barrel, mouthpiece and reed. A high saxophone? The best notation is soprano-like at all heights, whatever reed the musician decides to use, with much 8va and 15a sopra, and double treble clef. ========== Could the flute use this system? Maybe perhaps. The high isolated holes would help the altissimo but demand a shorter head than usual despite it's not cylindrical. Stronger finger movements need also something to hold the body more firmly. ========== Hints at the keyworks could come. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

I've bought 1kg of palm oil for 1.5€ and while I wouldn't put that in my stomach, as a cork grease it's fabulous for music instruments. Tallow must have been that good. Zero odour, vegan, no known allergies, should fit many faiths. Share the 150¢ among 60 musicians if you wish. Or repackage in 15g units and sell each for 5€. Few reasons exist to improve over that, with chemical treatments or from a different start. The indicated shelf life is one year, so time will tell if it smells. The added canola oil leaves a hard grease that takes longer to rub, no drawback for me. Playing only indoors, I can't tell the sensitivity to temperature. Marc Schaefer

-

Woodwind Materials

I had thought cork grease and keyworks oil would benefit from elaborate synthetic alkanes, but just vegetable oils seem excellent, and wouldn't evaporate over decades. As simple as palm oil as a grease, palm kernel oil as a light oil, maybe treated a bit more https://www.chemicalforums.com/index.php?topic=56069.msg360960#msg360960 For sure, they're cheaper than cork grease selling for 5€/15g.

-

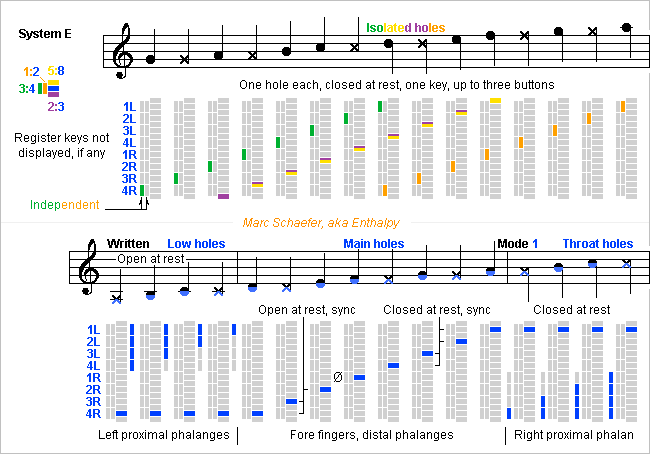

Woodwind Fingerings

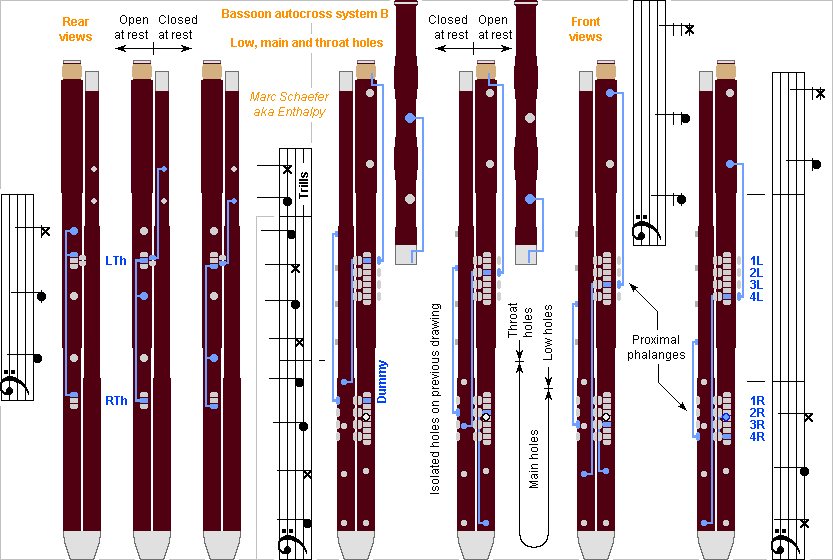

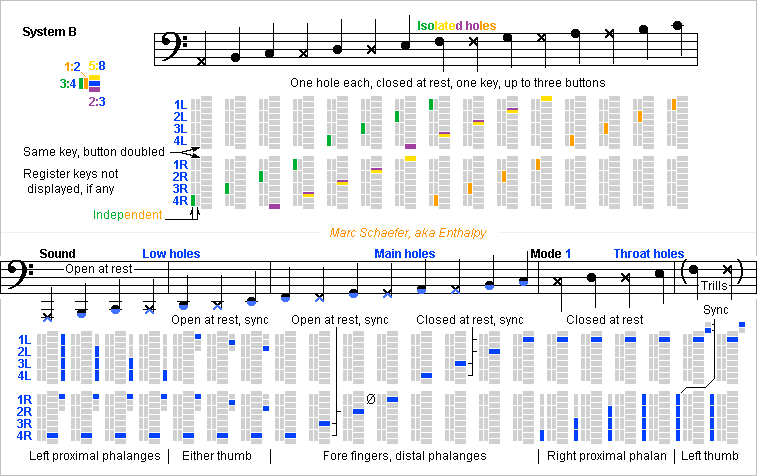

Following the isolated holes on Jan 19, 2019, here is a possible aspect of the low, main and throat holes and keys for the bassoon system B. There are 19 low, main and throat holes, covers and keys, most with a single button. Two covers at the bell have a transmission between their interrupted keys. Three covers have a button for each thumb. Total 34 holes exceed a Heckel system (around 29 holes). My even system D instead is simpler than Heckel, but without quasi-automatic cross-fingerings scienceforums The individual keys seem simpler and quieter than a Heckel system: no transmission between front and rear, one moving part per cover, very few adjustments, small parts on shafts. Wide thin tubes would stiffen the long shafts scienceforums and next The synchronization among right hand covers, left hand covers, thumb covers is not displayed, example there scienceforums The trill covers don't really need synchronization after all. The F# main hole is below the buttons despite being displayed. The whole right hand could shift higher so 4R is directly above this cover, or it could reside between covers. Some centre front locations pass 11 shafts in some 30mm width, I didn't try to show that. Several layers help, concentric shafts too, but that's overcrowded. CAD would help. Lone hole keys could be a top layer and be mounted last. Depending on material cost and availability, the narrow and wide joints could be a single part. Carrying on both shoulders, I care little about weight. I know no cost for LCP, but polyketone is cheap scienceforums - scienceforums Marc Schaefer, aka Enthalpy

-

Woodwind Fingerings

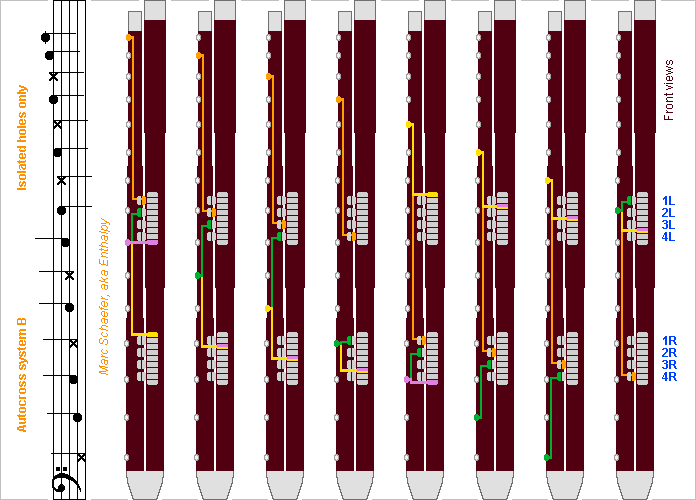

Here's a possible aspect of the isolated hole keys for the bassoon system B. I display isolated (or lone) hole keys only, hence only the narrow and wide joints. Keys for low, main and throat holes may come later. The fifteen keys fit on eight lines which have individual views. Each key is a single part without transmission hence silent and has one cover and one to three buttons whose function colour the key. Electroforming scienceforums can make thin tubes and parts for light stiff leys. All shafts can hold between conical screws here. Three shafts over a static long axle would save one shaft line. Concentric shafts would accept fewer lines. Guides like on a saxophone may help the long shafts. Three covers that are far from shaft ends need special measures. A bitmap drawing can't tell how to arrange the shafts. Maybe two layers of four shafts, with arms that pass over the main hole keys. This imposes a sequence to mount and demount, alas. ========== The four main hole covers and shafts opened by the left hand at the narrow joint's bottom would sit at the side of the lone holes and shafts, nearer to the wide joint. The right hand closes three main hole covers at the wide joint's bottom. Their shafts can run at the side of the left hand lone hole shafts, nearer to the wide joint. Grouped shafts give comfort when pressing several buttons. The thumbs' low holes can sit at the wide joint's rear, the left hand's low holes at the outer side of the wide joint and bell, the right hand's throat holes at the upper outer side of the narrow joint, and the trill covers at the narrow joint's rear. ========== I'd have the main connection between both joints, permanent and stiff in all directions, around mid-height if aesthetics permits. The carrying ring is nearer to the centre of gravity there, and at the wide joint side please, so the instrument orients naturally well. Other connections near the ends should allow different expansion. All holes in the narrow joint are at the dry side. Their covers could be forced open in the transport case with few foam wedges that press the buttons. Marc Schaefer, aka Enthalpy

-

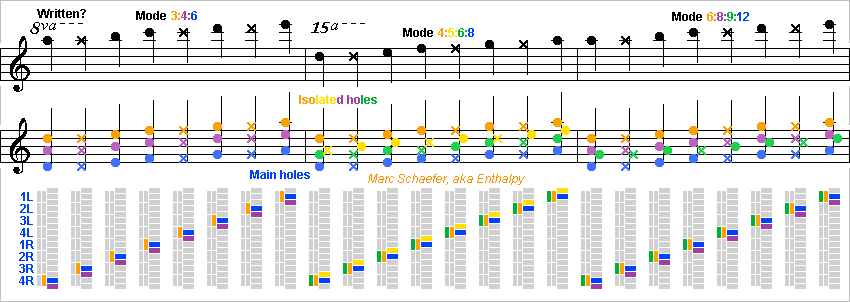

Woodwind Fingerings

The automatic basson system A can't let the 3:4 (green) key just push on the 1:2 one (orange). I had proposed it on Dec 30, 2019 scienceforums but the pushed key would get open also when the pushing key opens for other ratios, which wouldn't work. A separate button can correct that. The musician never presses the 3:4 directly, but rather this button that pushes on both 3:4 and 1:2, which are independent from an other. 1:2 remains directly accessible with its button. This needs one part more per upper finger, articulated like the others, and one set of adjusted corks more, with failure risks and noises. ========== The present system B basson with quasi-automatic cross fingerings keeps all keys independent and adds no separate button. The musician must hence press both buttons, 3:4 (green) and 1:2 (orange), for the modes 4, 8 and 12. I've grouped them to enable that. The rest is the same as system A: the modes, their span... I've indicated buttons for separate throat holes that avoid compromises. System B keeps the instrument's aspect and holes of system A depicted on Jan 12, 2019. 4R moves up to 6 covers so the spring force should be minimized. I've displayed the 3:4 and 1:2 buttons at the right of the main buttons for the right hand too, hoping to reduce the force and to simplify the keys, but if 1:2 is too difficult to catch without 3:4, then both can go to the left of the main buttons. Marc Schaefer, aka Enthalpy

-

Music Instruments Parts

Hello fellow bassoon players! (Plural just in case) Shoulder straps or harnesses carry bassoons at the boot, or the joints might separate. This is much below the centre of gravity. An extendable part can fasten the strap higher on German bassoons, French ones typically lack it. Also, the holding point is always between both bores, supposedly because wood is thicker there, but when playing the tenor joint is almost above the bass joint, so the bassoonist must roll the instrument manually. Here's my makeshift solution to carry comfortably a bassoon, in this case a French system. It's comfortable and can inspire a durable elegant design. The strap still pulls at the boot so the joints won't separate. But it (or some textile prolongation) makes a detour at a part attached to the tenor joint permanently. The strap pulls nearer to the centre of gravity, and more at right side. With proper adjustment, the left hand must pull a bit but no roll effort is needed, very nice. My part is a ring that surrounds the tenor joint. Then it must be thin: it's few turns of adhesive tape in my embodiment. More adhesive tape holds the ring up and right in adjusted position. It takes several plies or a thicker tape; ruptures made no damage. My textile prolongation is a brand new shoe string. No, it's not Mali here, but a marketable version should improve few details. The tenor joint has thick wood where the long side holes converge to the hand, at a place that can hold the part. Maybe the part must be open or openable to introduce the strap easily. Marc Schaefer, aka Enthalpy

-

Woodwind Fingerings

Erratum: on the last drawing of Dec 30, 2019, the four buttons for the lowest notes should be on the other side. ========== I could keep the nice bassoon's aspect with the system A automatic cross-fingerings. The hands' position are kept too. No tenor and bass joints separable from a boot here; instead, the narrow and wide joints can be of separate raw material but are kept together for transport. To clean the bore, the U-turn is removable, of usual or modified design scienceforums and next Undisplayed parts link the narrow and wide joints. They must be very stiff, collectively in all directions. Their shape change the instrument's aspect, for instance to resemble a Heckel system. Already the cover for the U-turn does much. The linking parts could carry many keys. The hole positions are approximative, both along the air column and around the tubes, which will depend on the difficult keyworks' design. All synchronised covers symbolised with arrows (for instance, opening C with 1Ld opens B, Bb and A too) sit next to an other on one same joint scienceforums Isolated holes use to sit close to a pressure node on all instruments. As opposed, throat tone holes are very inductive and sit one to three semitones higher than the pressure node on my French bassoon. Timbre demands it on a double reed. Whether the main transition gives the natural series of harmonics then? On my bassoon it does for some notes, for others not. Is it desireable? Maybe. In case a mode is a semitone higher than the natural series, reorganised buttons can play it. I only doubt that all notes in a mode shift by the same amount, and that all modes land on tuned notes then. Bassoons have no identifiable barrel in their bocal, maybe it would help. Adjustments there, and as usual downstream, tune the higher modes. The positions of the isolated holes influence the height too, but pulling too much degrades the emission and muffles the sound. My sketch suggests six main holes at the throat for the high first mode, rather than misusing isolated holes with bad compromises. The right proximal phalanges shall operate them, plus the thumb for trills, unless mode 2 can start lower for trills. If the sound gets shrill with many open isolated holes at high modes, consider split isolated holes scienceforums They can serve for the throat main holes too. The aspect of the keys might come. Some day and maybe. Marc Schaefer, aka Enthalpy