Everything posted by Enthalpy

-

Quick Electric Machines

Turbofans use presently to equip planes faster than propellers do, and have a rectifying stator stage behind the fan rotor. The stator blades hold also a casing than reduces blade noise. With electric motors, which depend less on fast air intake, the fan would rather sit behind the motor, and the stator be a permanent vane stage before the rotor. Orienting the vane blades would give more control over the fan operation, as at fighter jets. Different orientations depending on the distance to the axis, using blades in several parts or deformable blades, would bring efficient operation as a regenerative turbine, as suggested in my previous message. This needs orientable rotor blades, not trivial. ========== If both the vane stage and the fan stage can rotate around the axis, the plant could rotate mainly the fan for propulsion, and let mainly the vane stage rotate for regenerative braking. Then possibly, the blades can have fixed orientations and shapes. This may need duct sections varied in flight. The vane and fan can sit far apart from an other, for instance upstream and downstream the electric machine(s). Marc Schaefer, aka Enthalpy

-

Quick Electric Machines

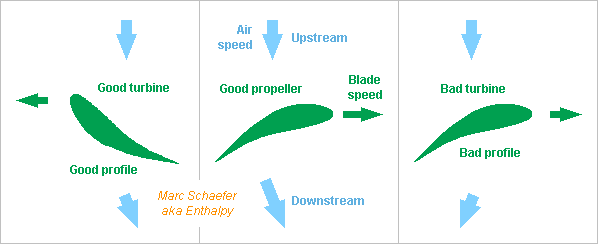

My proposal has imperfections too. As the circumferential speed decreases at a blade near the propeller's axis, the blade is built twisted to maintain everywhere a good angle of attack in the upstream air speed. Alas, this twist has the wrong orientation in my turbine operation. This increases the drag near the turbine's centre, where the blade moves flat in the wind. Mitigations must exist: reduce the twist, increase the blade-to-air speed ratio, reduce the blades' lift near the centre with a narrow round profile or a wider nose. If gearless, the electric machine favours a wider nose too. Whether this propeller-turbine is better than a nearly-symmetric profile? No qualitative answer. Maybe a vane stage can deflect the air before the turbine, by an angle that depends on the distance to the centre, and be retracted in the nacelle during propeller operation. This looks easier if the propeller sits behind the motor.

-

Quick Electric Machines

As electric aeroplanes develop, efficiency wants them to use the propellers as turbines to charge some accumulator during the descent. Most electric motors double as efficient generators, but good asymmetric profiles for propeller blades make bad turbine profiles as on the right part of the sketch, because their curvature has the wrong orientation. A symmetric blade profile would improve a lot the turbine operation, but is less efficient during the more important propeller operation. I propose (but didn't check if this is already done, as usual) to reverse the rotor's rotation as a turbine, as on the left part of the sketch. Then, the accordingly oriented blades have the curvature in the adequate direction, hence can be asymmetric and efficient for both operations. Most electric machines are good in both directions. Marc Schaefer, aka Enthalpy

-

Expansion Cycke Rocket Engines

Heard recently about the new company Isar Aerospace developing the Spectrum launcher Isar Aerospace - Spectrum launcher whose general design is a close copy of Falcon 9, with 1 Aquila engine at the second stage, 9 Aquila at the first stage, liquid oxygen and an unspecified "mix of light hydrocarbons", to put 1000kg in Leo or 700kg in Sso. The launcher is meant for constellations. As they hire design engineers for basic motor components, the design might still evolve. So here are my 2 cents. Electric pumps (in this discussion) reach easily Sso with two stages. They're easier to restart, simpler to develop, maybe cheaper, and turbines can replace the electric motors later. A common set of actuators can move the 9 first-stage engines. This avoids collisions and can be lighter and cheaper. A (turbo-) pump common to the 9 engines can be cheaper. But it goes against design reuse and redundancy. scienceforums Spectrum is as sleek as Falcon-9 but the next big thing, the sunheat engine, needs wide fairings scienceforums and more Thoughts about igniters there, for instance with a Diesel hotplug nasaspaceflight A new engine and launcher can burn amines. Easier to produce than synthetic hydrocarbon homologues, some are industrial compounds, gain 3s, denser. Comparison of launcher sizes there chemicalforums Examples of very safe and of more efficient amines there chemicalforums - chemicalforums - chemicalforums Heavier hydrocarbons (pinane, farnesane etc) or amines (Pmdeta etc) aren't easily flammable. chemicalforums I would not replace them with dangerous methane for its small gain. Spiropentane and cyclopropane are denser and more efficient. Unstrained light alkanes are both dangerous and no better than heavy alkanes. Some strained heavy alkanes seem reasonable to produce, safe and 5s better than "kerosene" chemicalforums Cooling the engine with oxygen would enable ethylene and other unsaturated fuels chemicalforums that gain 2s-6s over methane and are denser. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

Bassoon balancer v3. The string coming from the boot joint is redirected by a loop that now has its ends parallel to the body, while the ring perpendicular to the body passes straight over the loop. This v3 is much easier to build and to adjust. Still adhesive tape, about 3 plies. At the loop, two foldings give 90° each, and an added short tape part neutralizes the sticking side. V3 too provides perfect roll balance and leaves some weight on the left hand, since an attempt with perfect pitch balance was unplayable. The adhesive tape always separates from the concave portion of the tenor joint, so instead of sticking it there, this time I gave it roughly the loose length left by the spacing to the bass joint. Marc Schaefer, aka Enthalpy

-

Solar Thermal Rocket

Nasa and Esa consider a mission to bring Mars samples back to Earth. The sunheat engine makes it much easier and enables a more ambitious mission. The artist rendering I saw recently suggest ion propulsion with big solar panels and small thrust. The sunheat engine brings a specific impulse similar to ion engines and a much stronger thrust for the same sunlight collecting area, so a heavier spacecraft can manoeuvre faster. I won't detail that.

-

Quick Electric Machines

The Atecopol collective spreads doubt about the hydrogen amount needed by airliners blogs.mediapart.fr (in French) "10 000 wind turbines just to feed the planes starting from Roissy" (France's biggest airport), so here are my figures. Some 240 000 airliners a year start from Roissy, needing about 10Mt kerosene that produce 0.4EJ heat. The better efficiency of fuel cells needs 0.2EJ/year from hydrogen. Engines that burn the hydrogen, as Safran would like, are nonsense. A 5MW terrestrial wind turbine produces mean 1.3GW or 40TJ/year. 50% yield to hydrogen takes 10 000 wind turbines, OK. Germany has already 30 000. These wind turbines cost 14G€ and save yearly 80 000 000 barrels kerosene. Crude oil at 40usd costs yearly 3G€, kerosene 7G€. The production pays the investment in 2 years, after that it's all profit. Very few investments bring money that quickly. This single operation would reduce France's trade deficit by 1/20th.

-

Woodwind Fingerings

On my old French bassoon, I bored a second piano hole just under the first one at the bocal, closed by the same long pad, hoping to ease and raise C#, D on second register and ease C#, D, Eb, E, F on the 4th octave. It did that more or less. The less expected effects: 4th octave E became as easy as the A below. 4th octave D became impossible. Good reason, I tapped the second hole. But the much easier E confirms it: one lone hole per semitone will let my pianolike system add a half or full octave to the bassoon at identically easy emission. Oboes and flutes should improve similarly. Marc Schaefer, aka Enthalpy

-

Intentional Losses in Wind Instruments

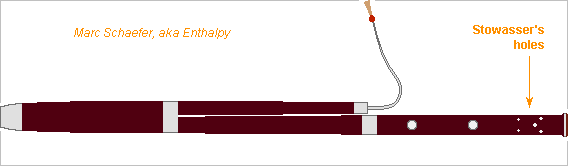

Most woodwinds have tone holes. Very wide on the Boehm flute and the saxophone, less so on the clarinet, very narrow at the throat of an oboe or basoon. tone holes are inductive, so the wave doesn't reflect fully at the first open tone hole, especially high harmonics or notes, and more so at narrow long holes. This dampens and detunes the high harmonics, a useful feature for a mellow sound. tone holes are also lossy, more so if narrow, and this helps match the reed where the tube is shorter, hence the narrower tone holes at the throat of the oboe, clarinet, bassoon, tárogató (but the saxophone does it too little and its octave jump is heterogenous). I should come back some day with more quantitative reasons. At their end, woodwinds should replicate the response of the tone holes set. Most have a flare there: it reduces the reflection of the highest harmonics by matching the impedance to free air, it detunes their resonance too, but a flare doesn't match the losses of the tone holes set, it even reduces the losses. The reed is too little damped there, it oscillates too strongly, and the sound gets readily harder, like when a guitar amplifier saturates. At the tárogató, Stowasser added many small side holes, always open, near the end. Maybe they existed before, since many oboes and a few clarinets have one open side hole near the bell, but I'll call them "Stowasser's holes". They imitate a tone holes set by spreading the reflection over the distance and by creating losses, especially at half-wavelengths not much bigger than the distances between the holes and to the end. At identical inductance, several narrow holes bring more losses than a wide one. Stowasser did that better, clarinets and oboes failed to copy it in a century, but you can see them in my instrument silhouettes. The heckelphone has a similar end plate. Stowasser put holes on two ranks. Better for the wood, but it also spreads the reflection more. Here the Fourier transformation of the distribution of the reflection tells the effect on the spectrum. If expressing the distribution as a convolution of positions and amplitudes, the spectrum multiplies the transformations of the individual distributions. With two hole locations plus the end, you get the product of two frequency responses and potentially more filtering. Here too, I should come back with more quantitative explanations, some day. What can improve over Stowasser: more efficient filtering results from equal reflection coefficients, between the holes and the end, and also at every elementary distribution of reflections. This needs bigger holes near the end and smaller ones farther, as can be seen in my instrument silhouettes. ========== The bassoon's bell has no flare: too wide and long. The French system has a narrower section in the bore, the German system has at least a wider section. Quite insufficient at my old Buffet-Crampon: the two lowest notes sound harder and need much embouchure adaptation. At its lowest notes, the bassoon should gain much from Stowasser's holes, the contrabassoon too. Same for low clarinets and for saxophones. This would need a slightly longer bell, but the bore can have narrower sections to save length. Marc Schaefer, aka Enthalpy

-

Woodwind Fingerings

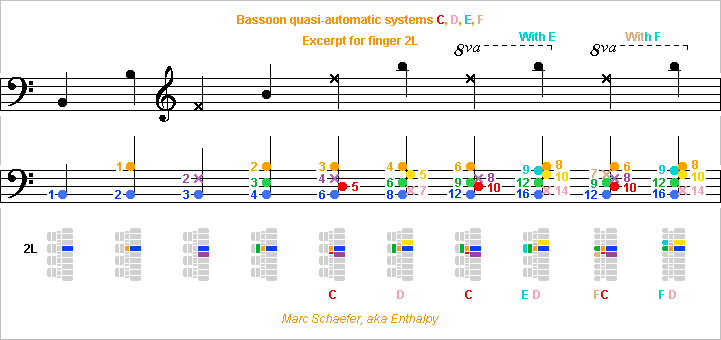

Here are (formerly quasi-automatic) pianolike basson fingerings C, D, E, F. These small changes to fingerings B are mutually compatible, except E and F. Their added buttons open more lone holes to ease high registers or add a register. Drawn for finger 2L only, with all options at once: System C adds a button (displayed red) per finger to open the lone hole three semitones above the main transition, in a harmonic ratio 5:6. Then, already the register 6 opens three lone holes in ratio 3:4:5:6, and the register 12 opens four, 6:8:9:10:12. The two lowest notes on these registers would need extra lone holes unwelcomed on the wide branch, or for simplicity these two notes don't open one lone hole more. One button more on an existing key is cheap, one hole more is expensive. System D adds a pink button per finger to open the lone hole two semitones above the main transition, in a harmonic ratio 7:8, alas imprecisely. Then, the register 8 opens four lone holes in ratio 4:5:6:7:8, and the hypothetical register 16 one more, in ratio 14:16. The three lowest notes would need extra lone holes on the wide branch, or they don't open one lone hole more. System E adds a turquoise button per finger to open the lone hole ten semitones above the main transition, in a harmonic ratio 9:16. They need no addition lone hole and stabilize the hypothetical register 16 with ratio 8:9:10:12:(14):16 - maybe. 14 results from option D. The main holes, all open below the main transition, help the emission as they contribute the ratio 16:17:18:19:20. System F shifts the E button to the top, so the next lower one, brown, doubles at nine semitones above the main transition and makes the harmonic ratio 7:12, alas imprecisely, for 6:7:8:9:10:12. Some buttons are quite small. The very inaccurate harmonic 7 risks to spoil both the intonation and the emission. The fingers must move even more covers. Which option(s) bring a net improvement? Trials shall decide. The body's shape, position of hands, holes distribution from system B remain. Marc Schaefer, aka Enthalpy

-

Solar Thermal Rocket

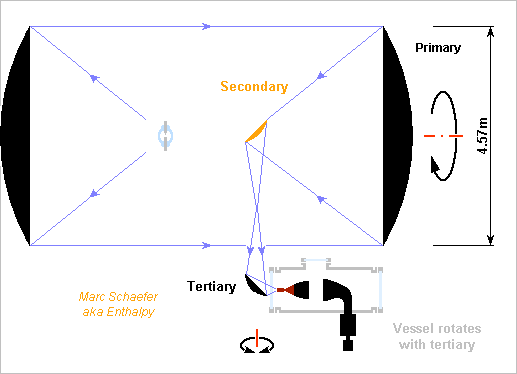

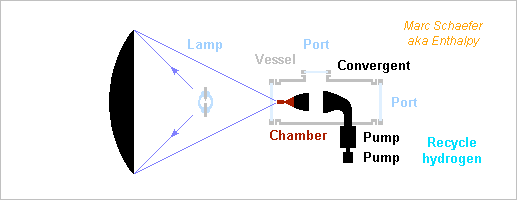

Thoughts about the chamber's experiment rig here under. I put far less time in the concentrators and don't plan to detail their development. The cryocooler is small, it needs experimentation in a normal lab. Thoughts may come or not, rather elsewhere, about the test ground for the multilayer-insulated hydrogen tank. ----- Light source ----- It must reproduce concentrated sunlight in space: same power per surface unit, at the same convergence angle that distributes the heat in the chamber. Sunlight on Earth can't. A xenon arc lamp is the usual and possibly only solution. D=2.8m concentrators for Vega-C need 8kW light for one Sun-Earth distance, D=4.57m for Ariane and equivalents need 22kW light. Single lamps achieve this. Extreme temperature for months defines much the chamber design, so the rig must test it. 24h operation is needed despite hydrogen and strong light. Spare lamps at hand are prudent. Cheap electricity is better. To protect humans and limit heat at the test vessel's porthole, I prefer that the lamp or a filter suppresses the UV. With identical power, the difference at the chamber is negligible. ----- Concentrators ----- An elliptic mirror shall concentrate the light from the lamp to the chamber being developed. It could be smaller than the flight concentrator but must distribute the power faithfully over the directions. Successive mirrors may help. Test of the real concentrator needs an additional big parabolic mirror that makes the lamp's light parallel. The vessel can then sit in between if the focal distance is meaningful without secondary and tertiary mirrors. The chamber can be tested with the optical path fixed, and the optical path steered without the chamber. Acceptable to me. Or in the optics of Jun 21, 2013 here scienceforums the axis from secondary to tertiary mirrors can be vertical, the primary rolls around its axis and the vessel and chamber rotate around the secondary to tertiary axis, with all piping and wiring. ----- Vacuum vessel ----- It hosts the chamber, maybe a last mirror, but not the primary, to save costs. Light enters almost concentrated through a porthole. More ports are desired for observation, assembly, and varied optical setups. The vessel must host the nozzle, D=0.37m for D=4.57m concentrators. The windows should be coated against reflections, absorb little the remaining wavelengths, and can receive blown air on the outer face. A flat window may alter only the focal distance but with chromatic aberration, while a spherical one centred on the focus could be slightly astigmatic, but I'm weak on optics. A diffusing diaphragm around the window is safer. Water cooling seems necessary in the vessel, to protect the walls in a faulty operation, and to cool the ejected hydrogen, whose stagnation temperature would fit tungsten only. A chamber for D=4.57m concentrators ejects 0.2g/s hydrogen and 0.08g/s for D=2.8m but pressure shall remain <<1Pa. That's a difficult task achieved by a big turbomolecular pump, not cheap. Second hand? An actively cooled convergent downstream the nozzle would help much. A primary pump is required too. ----- Hydrogen ----- 0.2g/s over a week-end is 43kg hydrogen, 500m3 at STP, or many 300bar bottles, dangerous. Over 3 months it's 1.5t, expensive and inconvenient. I couldn't find pleasant ways to produce slowly in situ neither. Better reuse the hydrogen pumped from the vessel. This may need some purification. The total hydrogen amount is then small. When switching between air and hydrogen, I'd purge all parts with nitrogen, which needs additional circuits and bottles. Ask an expert. ----- Fabrication ----- The mirrors and the lamp mount could be subcontracted, because people protection, surveillance sensors, and distribution over spectrum and angle aren't trivial. The vessel could be subcontracted. Or adapt a second hand vessel to the task. Hydrogen piping, with the purge design, sensors and certifications, could be subcontracted. Marc Schaefer, aka Enthalpy

-

Solar Thermal Rocket

This is how I imagine the development of the sunheat engine. ----- Chamber ----- It needs a very small team, with at least one scientist of very broad knowledge, and 1-2 more people used to innovate. A team of more specialized people may achieve it, or not, and less well. A bigger team would not work proportionally faster. A experiment rig is indispensable, available exclusively to the team all the time. Reformulated: computer simulations followed by a short experimental verification at an external facility would fail. The concentrator used to develop the chamber provides the power, power density, convergence angle of the flight model. It differs by the mass, materials, fabrication, lack of deployment. ----- Concentrator ----- It needs at least one mechanical designer used to space hardware and innovative designs. Expertise for optics, heat and control could come from a separate brain if needed. Expertise for launch environment, resistance of structures, space environment, deformations in operation, materials, fabrication processes should be available in the designer's brain. A team of more than 2 people would not work proportionally faster. Both teams can share people. The concentrator development can start immediately or once the chamber shows convincing results. ----- Tanks ----- The vacuum-insulated tank technology I proposed doesn't still exist, though Ariane 6 probably adopted it and future aeroplanes too. It's a significant development too that needs a specific test ground and can be sold separately as hardware or technology. Very few people, no banal knowledge, one year. Missions to the outer space need for the hydrogen a cryocooler I described elsewhere. It should have existed for decades at least for oxygen, but was neglected. The uneasy development is less exotic than for the chamber. Can be sold separately as hardware or technology. Few people, 2-3 years. Missions to Geo, the Moon, conditionally Mars, need no cryocooler, nor does a demonstrator of the sunheat engine in Leo. ----- Company ----- If a company is created especially, the burden needs at least half a seasoned person for months. Selling the engine or the technology needs later a salesperson who knows the people and habits of the space activity. The lab for a Vega-sized demonstrator can be normally tall with a good area and wide doors. For Ariane or Falcon 9, the lab must be 3 stories tall. Hydrogen, strong lamps and 24h tests need detectors and access control. ----- Dough and proof in space ----- All these developments are rather affordable. I evaluated in 2018 in a rich country to 400k€ the development of the chamber alone. Scaling for varied launcher sizes needs limited development. Add the concentrator and the tank, and for 2-3M€ you define the future of space travel. - BUT - Customers want flight-proven hardware before they design a mission around it. The sunheat engine can't be very small, and mission planners may want the real size proven in flight. Sharing a launch isn't easy neither, as the definitive concentrators are as wide as the fairing enables. Problem: a launch on Electron costs 6Musd, on Vega 20M€, well over the development cost. This is a toxic combination for the startup company I had imagined. Unless a small cheap seat can be found on a launcher (which is technically difficult), the business model of a small company selling hardware looks now bad to my eyes. Maybe an agency or bigger company shall develop these technologies, or a smaller company sell them the technologies before they have flown. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

I reported palm oil here on January 31 scienceforums and someone reported success with bag balm on corks wikipedia so I tried. The composition varies a lot, I chose the weakest smell at the drugstore, this one contains petroleum (from mineral oil), paraffin (again from mineral oil), and in third position vegetable oils, plus minor things that don't lubricate. Very efficient lubricant too. The consistency makes spreading easier that the solid palm grease. The weak smell is too much for me, so I go back to palm oil. Individual choice of course. To understand why the oil must be replenished, I impregnated paper with palm oil 2.5 months ago. Despite ~57 C+O atoms per molecule, the paper has significantly dried now. I believe this is evaporation, because palm oil isn't sensitive to oxidation, and the paper feels grainy and looks more opaque again. However, evaporation is too slow to require new oil on the corks after a week. Meanwhile I must clean away oil from around the corks, so it's just swept away by repeated assembly and disassembly.

-

Quick Electric Machines

The French government too wants to fly in 15 years airliners with hydrogen, fuel cells and electric motors ouest-france - bfmtv (both in French) Safran, a manufacturer of gas turbines, answers "burn the hydrogen instead". The others big actors answer "ambitious" despite the motors are obvious, the fuel cells exist already in Japan, and the tanks are a low-tech I described already. Start-up companies fly their demonstrators presently, with designs meant for the market. They would achieve airliners ahead of the big companies, if they were allowed to.

-

Music Instruments Parts

Second version of my bassoon balancer of January 17, 2020. The excellentissima idea is kept: hold at the boot, pass through a ring added at the tenor branch. The ring is added higher on the tenor branch and this relieves the left arm. It has two turns of adhesive tape around the branch plus the length for a gamma eye. It crosses the concave part of the tenor branch, where it separated over time, which doesn't hurt. A professional embodiment must improve that too. The ring passing between fingers 2L and 3L was only a tiny bit too high, so a longer gamma may enable it. Sewing thread tightens the gamma. This stabilizes the side position of the gamma to achieve perfect roll equilibrium. Also, the ring doesn't pull any more sidewise nor away the adhesive tapes at the pictures' left that hold it upwards. Marc Schaefer, aka Enthalpy

-

Music Instruments Parts

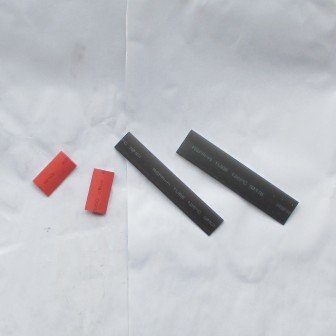

Maybe drawbacks like creep will appear over time, but after one daily training, the heatshrink sleeve works. I noticed no playing difference with cork, but couldn't compare both on real time neither. The tighter fitting immobilizes the bocal as I wanted, but tighter cork would do it too. Up to C# (just below the Sacre) where the comfort zone of the musician and the reed end presently, I noticed no difference; maybe things change at higher notes. These are the bassoon bocal without its cork, pieces of heatshrink sleeve, the bocal with the sleeves, and a zoom. The Chinese made the material affordable. It comes in many diameters and colours, length is commonly up to 1m. The diameter shrinks strongly and irreversibly at heat, from a hairdryer, a soldering iron, or with care from a lighter. Two plies happened to fit at my bocal, first with grease, later without. At first try, the shrunk sleeve moved around the bocal, so I held it with instant glue, which could be applied because the bocal is conical. ========== What can improve? Each ply is too thick and stiff for an adjustment, I had luck. Also, the conical bocal holds in an inverted cone at the bassoon. Maybe double-sided adhesive tape below the sleeve can adjust the diameter and slope if it resists the heat. Or a thread wound below the sleeve, which would give some elasticity. Heatshrink tape exists too, which enables big diameters, but I expect leaks where the tape ends. Below a sleeve maybe. Would it be thinner? Marc Schaefer, aka Enthalpy

-

Music Instruments Parts

Where woodwind joints fit in an other, cork makes them airtight usually, or formerly a wound and impregnated thread. I try heatshrink sleeve at my bassoon's bocal presently. At least, it needs no skills. The result is stiff and can minimize the dead volume, which should ease the altissimo. Details should come. Trials not today, it's too late. Marc Schaefer, aka Enthalpy

-

Quick Electric Machines

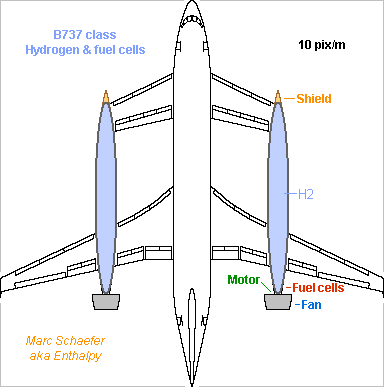

Here's a Burt Rutan's Voyager-style B737-class airliner with two hulls for hydrogen and one for the passenger and crew. The cabin and the D=2.2m L=19.2m ellipsoid tanks are to scale. The centre of mass and the wing area are not significant. These longer tanks cumulate 2/3 of the cabin cross area and are sleek, plus the rear fan interacts favourably with their drag. This design might improve the drag. A tandem, where the front wing extends beyond the tanks, is possible too. Marc Schaefer, aka Enthalpy

-

Quick Electric Machines

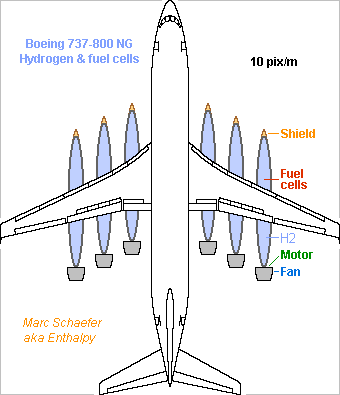

Here's a Boeing 737-800 NG with hydrogen nacelles. Six D=1.6m L=13.1m ellipsoids carry the hydrogen. Their construction is already described. They cumulate as much cross-section as the cabin but can be sleeker. Six tanks improve that over two, and they take less height. They are away from the cabin's doors. Motors being cheap, I prefer one per tank. More fan area improves the efficiency. The rear fans interact favourably with the drag. Exchanging electricity suffices for redundancy, while the hydrogen doesn't leave the nacelles. The nacelles' pylons can carry the fuel cells and also the flap actuators. The tanks are exposed below the wing. I used to consider it a drawback, but at least a controlled belly landing separates the hydrogen from the travellers. This design adapts to other plane sizes and ranges. Marc Schaefer, aka Enthalpy

-

Hear Conical Brass Instruments

They are not nearly conical. Why did you believe this obviously wrong assertion that is so easy to check?

-

Quick Electric Machines

Airbus' Press officer said few years ago that an "electric" A320 would have very limited transport capacity and range "because batteries are too heavy". So here are figures about a Boeing 737-800 NG with hydrogen and fuel cells. The B737-800 can take 26.0m3 = 21.1t kerosene. wikipedia 42% efficient engines transform that to 0.39TJ at the shafts. 60% efficient fuel cells and 95% electronics and motors make this energy from 5.7t liquid hydrogen in 5.7t tanks as described on Apr 14, 2013 here What's the peak power of one CFM56-7B26 kerosene engine? wikipedia Its D=1.54m fan pulls up to 118kN while the Trent 800's D=2.8m fan pulls up to 415kN. The Trent 800 can produce 36MW at the shaft, which scales to 9.9MW for the CFM56-7B26. Fuel cells for the Toyota Mirai weigh 0.5kg/kW wikipedia so 2*9.9MW need 9.9t fuel cells. The hydrogen, its tanks and the fuel cells sum 21.3t, as much as the kerosene. Motors replace the 2*2.4t engines, this should save mass, with a gear definitely. 80m3 hydrogen fit uneasily in the present design. I dislike the old proposals of a long tank above the passengers. Six long tanks could hang under the wing together with six motors and fans. Ellipsoids would be D=1.3m L=15.2m plus some insulation and shock-proof fairings. The long-range B777 Dreamliner would draw the same conclusion: hydrogen + tanks + fuel cells 20t lighter than kerosene, but the volume fits uneasily. So while the short-range Dornier 328 can just upgrade its nacelles to hydrogen September 16, 2018 here medium and long-range airliners need stronger adaptations, or better a new design. Drawings may come, later hence maybe. Marc Schaefer, aka Enthalpy

-

Quick Electric Machines

A potential target for quick electric motors are vacuum cleaner. In the ones I know, a series-connected motor provides the 50m/s to the centrifugal compressor. Well proven, but the commutator and brushes wear out and cost something to produce. It adds also noise to the compressor's one. A brushless or a squirrel-cage motor would improve the reliability and noise, with proper design for the brushless. The drive electronics costs little (processor fans have some) and saves the commutator. The present series-connected motor may rotate at 20-30m/s as the compressor is wider than the rotor. A squirrel-cage or brushless motor rotates easily at 100-150m/s, which saves motor mass. Does my graphite fibre winding around the rotor bring more? Not sure. Quietness speaks against supersonic rotors. The engine's shape, short and wider than the compressor, would also be less convenient. But to improve the pressure, yes. ========== Quick electric motors would improve turbomolecular pumps for deep vacuum. They must rotate as fast as possible as compared with the molecules' speed, which is about Mach 1, or quite a lot for the residual hydrogen. An impeller of good aluminium can move its tips at >400m/s, expensive steel faster. Fast brushless or squirrel cage motors achieve ~200m/s at the gap. My graphite fibre winding doubles that, for a much shorter motor easily built. ========== Hydraulic pumps must achieve 210, 350, rarely 700 or 1500 bar. They are piston pumps typically. For 350 bar, a single staged centrifugal pump needs 350m/s tip speed, reasonable for good steel. 700 bar needs excellent steel, 1500 bar two stages. The centrifugal pump would be much smaller and silent than the piston pump, potentially more reliable and cheaper too. It needs a quick motor. Here too, a 400m/s rotor outperforms a 200m/s one. ========== High-pressure water jets clean façades, hard grounds and more. 500 bar or more result usually from a piston pump. A smaller, more silent and potentially cheaper centrifugal pump would achieve 500 bar from 370m/s impeller tip speed, reasonable for good steel, and 1000 bar from 526m/s, still accessible. Again, it needs a quick motor, and a 400m/s rotor outperforms a 200m/s one. ========== High-pressure water jets cut metal sheets. 2000+bar result usually from a piston pump. A smaller, more silent and potentially cheaper centrifugal pump would achieve 1000 bar from 526m/s impeller tip speed, accessible to excellent steel. The higher pressure would need few stages. A 400m/s rotor outperforms a 200m/s one at the quick motor. ========== Every German hobbyist has a "Minischleifer", a hand-held 130W+ 30,000rpm electric motor that spins grinding, polishing, milling, drilling bits. No idea how common these tools are elsewhere. I've seen only motors with a commutator and brushes. They are noisy, sensitive to the abundant dust, clumsy, and they get hot. A fast squirrel cage would improve that, a brushless motor of silent design even more. The casing would enclose completely the stator and have surrounding blown fins as usual for squirrel cages, gaining much reliability at once. The more efficient motor would run cooler. Without commutator, the motor could run on a safe voltage like three-phase 48V instead of 240V. The present alternative is 12Vdc, where the commutator limits to meagre 20W. Present rotors move at 50m/s, an awful lot for a commutator, easy for a squirrel cage. Shall this increase? The diameter can't. Maybe some tools accept more speed, nothing obvious for polishing or grinding wheels. Tools with a smaller diameter may be interesting. But a shorter, lighter and cooler motor would be welcome. Marc Schaefer, aka Enthalpy

-

Hear Conical Brass Instruments

One more musician playing the cornetto nicely: Gustavo Gargiulo - gustavogargiulo.com/press - His Youtube channel

-

Woodwind Materials

The company Vibrato markets plastic saxophones, with walls of moderately thin polycarbonate, and even pads of elastomer. Here it there IruxMK3p_jY Plastic vs metal vTZzFIt2raw at t=58 Plastic G5ev6izRxpM Both The difference is huge. Thin polycarbonate makes a muffled tone and sounds just like plastic. Exactly like a plastic trumpet does, or the clarinet of thin injected plastic I tried years ago. The records can't tell how much the covers and pads contribute. At the oboe with thick walls and normal covers and pads, polycarbonate didn't behave that poorly as compared with Dalbergia. Some physicists still claim the material has no influence, essentially because they can't explain it, and because an influential ancestor botched that. Flawed reasoning. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

If stretched or rolled polyketone becomes stiff and keeps damping, it can make a superior material for wind instruments. Marc Schaefer, aka Enthalpy