Everything posted by Enthalpy

-

Brass Instruments Materials

I heard it about saxophones too. Silver shall give a more brilliant tone than varnish. But how much do the eyes mislead the ears? And while a saxophone body can vibrate, how to explain the alleged effect at a bassoon bocal? For flutes, I had the golden opportunity to compare materials at the head 111316-woodwind-materials I could convince myself there was a repeatable difference, but more in the response than in the sound, and it would be imperceptible through computer loudspeakers. The flute body should matter more than the head. But if we hear the plastic at a trumpet record, in real life it must be striking, just like it was at the clarinet. I just love the way professional musicians tell "Absolutely amaaazing" about the piece of junk in their hands to earn their two bucks. Oboes exist of PMMA and, even over PC loudspeakers, they sound just like plastic. 111316-woodwind-materials NrJy8tNlBuQ 1:55, same musician and reed, different materials 8AJnQk3ECYE 0:38 So would polyketone or LCP sound better? Acoustics had difficulties to explain the effect up to now, which let some people deny it. That would be a mistake to my opinion, as the acoustics of musical instruments is difficult, and we know so little about sound perception. I hope to have found explanation candidates 111316-woodwind-materials 111316-woodwind-materials and plan to search credible explanations for brass too.

-

Woodwind Materials

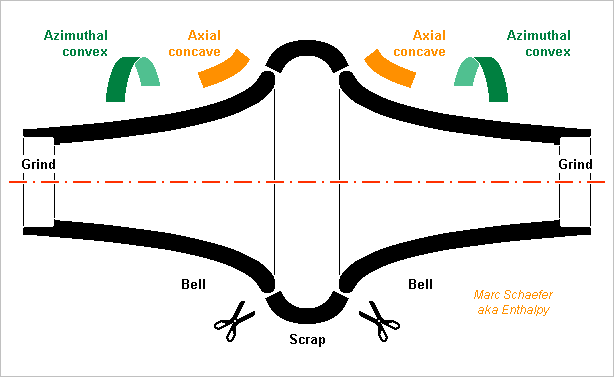

Wound filaments are commonly impregnated with a thermosetting resin. A molten thermoplastic would be nice, since polyketone, LCP, ABS, PP are vibration dampers and resist humidity better. Or could the resin be dissolved to impregnate the filament for winding? I could make a glue for ABS by dissolving ABS chips in trichloroethylene or maybe acetone. Ketones supposedly dissolve polyketone and exist with any evaporation rate. A warm mandrel would evaporate the solvent faster there. ========== As a variant of the idea of Dec 16, 2018 here, filament winding can make two bells at once. This doubles the production for nearly the same human effort and reduces the scrap. The winding head also moves between nearly cylindrical ends, which should be simpler and enable a cheaper machine with fewer axes. Winding can provide thicker ends where the bells' inner face is ground. Marc Schaefer, aka Enthalpy

-

Brass Instruments Materials

Thanks for your interest! I have no personal opinion. I only play the contrabass tuba among the brass, and very badly. I'll search for the video where Allison Balsom tries a trumpet of injected thermoplastic. She reverts very quickly to a metal mouthpiece, and then she finds something not too unpleasant to tell about the instrument - but you just hear the plastic. It's one trial that needs no lengthy wondering and interpretation. The effect is very similar to what I observed with a clarinet of thin injected thermoplastic. The difference is huge, and not in the right direction. Maybe the explanations I proposed Oval resonances Bending resonances bring some enlightenment, as the figures could fit. Or maybe not. But It's a reasonable assumption that the polymer's lower E-modulus is the reason, so I suggest to try a stiffer polymer, optionally loaded with graphite choppers. ========== Here's the video with the p-trumpet: NLAHSgZaMU0 music 0:51 it sounds absolutely dull, so the plastic mouthpiece (at 3:10) doesn't make much hearing difference to me. And easy blowing, yes - just like the thin injected thermoplastic clarinet I tried. Both aspects reveal huge losses at the walls, which should logically result from the lack of stiffness. ========== A more direct opinion by an other trumpet player, supposedly not paid by the manufacturer, there s7Uv5Ld0sJU absolutely dull sound (he doesn't tell it like that). He finds a difference between a plastic and metal mouthpiece. Both instruments intonate terribly, especially on low notes. I suppose it's a problem of shape more than material.

-

Woodwind Materials

Here's one company that makes instruments with bells and necks of graphite fibre composites: dacarbo.ch with jeccomposites.com using graphite filaments plaited in situ and fabrics. I believe filament winding would save human labour. Other polymers may be more durable and damp better than epoxies: polyketone, LCP?

-

Woodwind Materials

Instrument parts were already electroformed. Conn made its "Coprion" trumpet bells starting around 1938 cderksen.home.xs4all.nl link there to a Conn flyer other sources are indirect: Bach and Schilke are said to electroform their silver bells, but I havent found the claim on Schilke's website. Here a manufacturer electroforms copper trumpet bells: dqscustomshop.com So at least it has worked, but the process didn't replace other methods. The electrodeposited metals are in perfectly annealed condition, and apparently the luthiers tried only pure copper and pure silver which are horribly soft then. Easily deposited nickel is harder even if pure, and nowadays alloys are deposited too, including Cu-Ni, Cu-Sn, Cu-Zn, Ni-Co and many more, while Ni-Mo, Co-Mo, Ni-Co-Mo and Ag-Cu, Ag-Pd, Ag-Rh look favourable. Electroforming boots, bocals and complete woodwind bodies with chimneys would save more time than trumpet bells. Electroformed keyworks would be lighter or stiffer or both, especially saxophone octave keys. This demands a hard metal. Ag, Au, varnish... can cover allergenic Ni and Co.

-

Brass Instruments Materials

Hello everyone ! Could liquid crystal polymer make mouthpieces for brass wind instruments? Mouthpieces are almost always made of metal presently. Wood is too sensitive to saliva, usual polymers sound badly supposedly because they aren't stiff enough. But metal is cold when playing outside or in a church. With high mechanical damping and 10GPa Young's modulus, more if loaded with graphite choppers for instance, LCP should perform better than usual polymers. If the sound is decent but differs from metal, it may fit some scores. At least Vectra A950 is authorized for food contact by the FDA. LCP can be processed by injection to make cheaper mouthpieces. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

Could liquid crystal polymer make mouthpieces for single-reed instruments like the clarinets, the saxophones, the tárogató? Mouthpieces are widely made of ebonite up to now, sometimes of metal or "crystal" (a glass variant). LCP would keep ebonite's warm contact, resistance to saliva, mechanical damping, and multiply Young's modulus by 5, which might ease the emission of the altissimo register. Loading increases the modulus further, especially with graphite choppers. At least Vectra A950 is authorized for food contact by the FDA. LCP can be processed by injection to make cheaper mouthpieces. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

A wind instrument with a mostly curved air column, as inspired by the Wagner tuba or the serpent for instance, is made easily by electroforming or by filament winding. Polymer injection would be conceivable for certain wall thicknesses. Intended for woodwind, this could apply to brass instruments too if desired. Marc Schaefer, aka Enthalpy

-

String Instruments

I suggested here on February 27, 2019 to use liquid crystal polymers (LCP), optionally loaded with graphite choppers, for parts of string instruments. This includes bow parts made of LCP, especially the frog. Whether LCP improves the manufacture or the play over Diospyros and Dalbergia remains to see, but at least it would preserve rare species and help the musicians to cross borders. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

Here on Nov 13, 2017 and Nov 26, 2017, I proposed the oval deformation of the wall around side holes to explain the material's influence. Curving the air column would stiffen the wall as it gets a curvature in two direction then. It can be significant with metal walls since they're thin usually. For instance a metal contrabass clarinet, a metal contrabassoon, a sarrusophone, a tubax... could be built with the air column curved all the way, like a Wagnertuba, some baritone saxhorns or a French horn are, rather than as straight sections connected by sharp turns. What makes little or no difference at brass instruments might improve woodwinds. Shall the flute be curved, a bit like the serpent was? That won't ease the keyworks, but it would shorten the alto flute and hopefully stiffen its wall, which is too thin and of bad alloy because of the weight. Marc Schaefer, aka Enthalpy

-

Bore width of wind instruments

I had believed Dr Zubke used some Buffet-Crampon for his comparison with the Heckel system f6DgNBHPw9o but it's an Atelier Ducasse bassoon, with significant changes ateliersducasse.fr The bore is narrow, as traditionally on French bassoons. The boot got a wide smooth turn. I thought this was standard on recent French bassoons. Ducasse proposes the French system or the Heckel on their instruments. Zubke plays the Heckel system on both, no miracle. Ducasse uses heavy stiff wood combined with a plastic lining. German systems use maple with lining. The piece starting at 52:03 climbs to E in treble clef, Zubke too comments at 52:50 that high notes are much easier in the French bassoon due to the narrower bore, and gives examples to 54:06. I keep open the possible further cause that stiffer wood too helps the high notes, just like grenadilla eases the piccolo's high notes against metal. A smaller reed made exclusively for the narrower bore would ease the high notes further.

-

Bore width of wind instruments

It's not a bassoon, but an ancestor: the rackett or cervelas had a double reed on a conical bore, and the long bass tube was folded many times to fit in a single compact cylinder. Rackett The original instruments belong in museums. Those played today are often very approximate copies whose users had no professor and usually spent little time learning the instrument, just to play a few notes of ancient music re-enactment. Though, this record has a decent sound, proving that the instrument isn't to blame: JIy86HTy9oc The musician hopes to improve the sound after practising.

-

Bore width of wind instruments

The full conference about French vs Heckel system bassoons, with exciting commentaries: f6DgNBHPw9o music begins at 52:10 I'm pretty sure the musician uses for both the same reed, which is too big for the narrower bore of the French system, so the comparison is a bit biassed.

-

Hear a tárogató

One more example of nice sound on a soprano tárogató by Attilio Berni v0tFp2_H3R8 at 8:50 many more saxophones and similar instruments on this fascinating record.

-

String Instruments

The Japanese koto and other string instruments have their soundboard made of Paulownia tomentosa (kiri) instead of spruce Koto at Wiki - wood-database.com - Paulownia at Wiki This broad-leaved tree provides lighter wood than conifers, even spruce: 280kg/m3 against 400kg/m3. Its lengthwise E-modulus is 4.4GPa against 10GPa, so the figure-of-merit E/rho3 is 200 against 156 for flexural wave speed at identical mass. Its fracture stress is 38MPa against 70MPa, so the figure-of-merit sigma/rho2 is 485 against 438 for bending resistance at identical mass. I have no other data: ER, ET, acoustic losses, ease of working... It grows very quickly, at Australian producers too, but the tree is undesired in the US hence its wood rare and expensive there. Japanese luthiers use it traditionally, so its other properties are known. At the linked wood-database.com, one luthier tells she prefers it over spruce for guitars. Worth a try at pianos? Bowed instruments? Others? At identical resonant frequencies, it would make soundboards lighter, hence louder and more responsive hopefully. Marc Schaefer, aka Enthalpy

-

String Instruments

The horizontal harp proposed here on February 24, 2019 could get a frame of cast magnesium alloy. Passing in the soundbox, it looks easy, lightweight and cheap. Magnesium, optionally the same part, perhaps with integral ribs, might compose the bottom and sides of the soundbox too. Fibre composites too might make the frame and optionally the faces of the soundbox not meant to vibrate. Of course, I have nothing against other alloys like aluminium or zinc, nor against assembling parts. And absolutely nothing against wood. Marc Schaefer, aka Enthalpy

-

String Instruments

Rods would be made by extrusion, not injection, so the unusual resin costs no new tool.

-

Woodwind Materials

Rods would be made by extrusion, not injection, so the unusual resin costs no new tool.

-

String Instruments

In this discussion on December 16, 2018, I suggested graphite-loaded polymers to replace ebony at fingerboards and other parts. Besides better known POM and PEEK, liquid crystal polymers are available as pellets too, and their properties seem excellent for parts of string instruments. A decently documented LCP is Vectra, from Ticona=Celanese: hipolymers.com.ar Compositions page 11: A is the most common base resin, E would have had higher losses. 9nn is pure, 2nn contains graphite choppers. Vibration damping page 22. Pure Vectra A950 has losses ~6% and E~10GPa while Dalbergia melanoxylon has losses ~0.6% and E~20GPa lengthwise, but E drops a lot in the R and T directions. With 30% graphite choppers, A230 offers ~3% losses and E~30GPa, stiffer than ebony. Lossy materials may improve the parts of string instruments that shall not vibrate - maybe, as theere is some debate about the violin's fingerboard. Can a musician safely hold this material in his hands many hours a day for 50 years? I'm no expert, but at least the unloaded resins A950, B950 and C950 are compliant with FDA regulations for food contact, page 33. I suppose Graphite choppers don't harm. Far less nice, the price page 11 is somewhere between PEI and PEEK, ouch. Neither did I see rods for sale, only pellets meant for injection, but Hoechst-Celanese did provide rods of A950 to a research team. Shall the luthiers contract a plastic injection company to make rods for subsequent machining, or rather to inject the net instrument shape? Good to know: Vectra gets anisotropic upon injection. Datasheets of A950 and A230: Selection - A950 - A230 at tools.celanese.com The A950 composition shows better Charpy (break by shock) figures than POM. Resilience drops with graphite choppers. Both compositions absorb very little moisture. Marc Schaefer, aka Enthalpy

-

Woodwind Materials

They are well known as top-performance fibres, but liquid crystal polymers are available as pellets too, and their properties seem excellent for music instruments. A decently documented one is Vectra, from Ticona=Celanese: hipolymers.com.ar Compositions page 11: A is the most common base resin, E would have had higher losses. 9nn is pure, 2nn contains graphite choppers. Vibration damping page 22. Pure Vectra A950 has losses ~6% and E~10GPa while Dalbergia melanoxylon has losses ~0.6% and E~20GPa lengthwise, but E drops a lot in the R and T directions. With 30% graphite choppers, A230 offers ~3% losses and E~30GPa. Stiff and lossy materials are rare and supposedly make better woodwinds. Can a musician safely hold this material in his hand and blow in it many hours a day for 50 years? I'm no expert, but at least the unloaded resins A950, B950 and C950 are compliant with FDA regulations for food contact, page 33. I suppose graphite choppers don't harm. Far less nice, the price page 11 is somewhere between PEI and PEEK, ouch. Neither did I see rods for sale, only pellets meant for injection, but Hoechst-Celanese did provide rods of A950 to a research team. Shall the luthiers contract a plastic injection company to make rods for subsequent machining, or rather to inject the net instrument shape? Good to know: Vectra gets anisotropic upon injection. Datasheets of A950 and A230: Selection - A950 - A230 at tools.celanese.com The A950 composition shows better Charpy (break by shock) figures than POM. Resilience drops with graphite choppers. Both compositions absorb very little moisture, excellent. What shall be the first trial: a piccolo or an oboe upper joint? And I want a bassoon of it! Marc Schaefer, aka Enthalpy

-

String Instruments

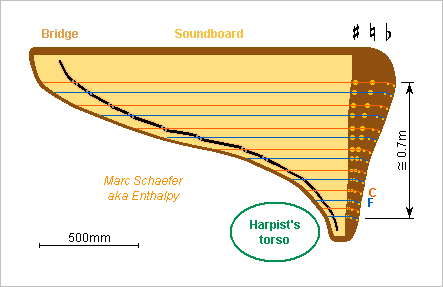

If a harp's string plane is horizontal and the musician plays from the top, the lower side is available for a big, unstressed, lound soundboard. A double-action diatonic concert harp could resemble a qanun and other zithers: 14 to 16mm spacing spread the 47 strings over 0.7m, letting small harpists lean forward or backward a bit. Both hands access the full range if needed but risk to collide at high notes. The playing technique is the same as on a vertical harp, excepted the less comfortable hands position, and I expect harpist to adapt swiftly. The equivalents of près de la table, sons xylo, harmonics and others look possible. The space between the natural and sharp disks can be straight, as on the sketch, for better action designs. Or the sharp disks could be aligned, or the soundboard's edge straight, and more - the strings middle line seems decent on the sketch, but the hands could look more to the right at high strings. Alternately, the action parts could reside below the soundboard, with plenty of room for a better design. A post for the pedals would usefully be removable or foldable, making the thinner instrument easier to transport than the vertical harp. The construction resembles a grand piano, notably the bridge where the strings can zigzag at two pins to inject no force in the soundboard, though a single downward bend might be good too. Stiff bracings and a closed box would give a deep sound; this can be adjusted to differ less from the vertical harp. An optional sound hole would reinforce low notes down to a cutoff; I'd put it at a side, not at the soundboard, and a rosace or many small holes would tame the resonance. Resonating doors, as described in this discussion on 03, 05, 07, 09 February 2019, apply here too. To be easily strong and stiff as on a piano, the frame can run under the soundboard rather than around it, best through the soundbox, and be of metal, wood, fibres... A removable hard cover, or a complete box, must protect the soundboard and strings. ========== A chromatic version would be simpler and could have two bridges, but as usual, it can't play the existing harp scores, and low strings must keep the 16mm spacing to avoid collisions, so the range takes an impractical span. The soundboard could carry several string groups side by side as on the cimbalom. This limits the playing technique. Or the individual range must be reduced and spread over two instruments. Good opportunity to start the low harp at the piano's A. 49 strings would then cover 4 octaves, and the high and low chromatic harps overlap by 1.5 octave. Marc Schaefer, aka Enthalpy

-

String Instruments

The best musical strings are still made from gut, possibly spun with metal wire. Gut is often replaced with PA11 polyamide or with metal, but nothing provides the crispy, profound and long sound of gut, for reasons not fully understood. Strength per mass unit is mandatory, very low mechanical losses too, density and bendability are useful, and I believe elastic strain matters. "Catgut" is one sheath of the lower part of the intestine of sheep, sometimes goats or cows, after mechanical and chemical processing which I understand leave only the collagen, in fibres oriented essentially lengthwise gamutmusic.com and web.mit.edu The upper part of the intestine made sausage casings, but for decades collagen widely replaces it because the process is simpler wikipedia Similarly, it would be nice to make musical strings of collagen, where at some process step collagen would be a homogeneous melt or solution, to obtain more easily strings of repeatable properties. The cited Wiki paragraph, brief and not quite clear about it, mentions: "It is widely used in the form of collagen casings for sausages, which are also used in the manufacture of musical strings." but I've never heard about a musical string made of collagen, far less a good string, so there must be hurdles. Yarn from collagen exists already and serves for medicine. Citing subchap 2.4 of: Biomaterials Science: An Introduction to Materials in Medicine By Allan S. Hoffman, Frederick J. Schoen, Jack E. Lemons "Reconstituted collagen is obtained by enzymatic chemical treatment of skin or tendon followed by reconstitution into fibrils. These fibrils can then be spun into fibres..." Gut is a raw material long enough for strings, but to spin fibres, tendon seems an interesting alternative. Or continue with gut if the strings are better. Wiki suggests that the exact spinning method is paramount to stretch and orient the macromolecules and transform weak polyethylene into ultra-strong Dyneema and Spectra Polyethylene fibre and Gel spinning at Wiki it seems logical: the lower exit temperature in gel spinning keeps the order acquired by the macromolecules in the spinneret. Whether this achieves strings as good as gut? Marc Schaefer, aka Enthalpy

-

String Instruments

Musical strings stretch the strongest materials to their limit. The string sound speed sqrt(sigma/rho) is 300 to 500m/s in music instruments, and where a string must be shorter, it is spun with metal wire over a thinner core that is still extremely stressed. Examples: Violin E. 662Hz, 325mm, 430m/s. Plain steel, 7850kg/m3 needs 1455MPa tension, and many E strings are overspun with aluminium wire. Was gut in the past, then estimated 1000kg/m3 needed 185MPa. Harp Eb. 625Hz, 287mm, 359m/s. Plain gut, 1320kg/m3 needs 170MPa. Harp Gb. 2973Hz, 78mm, 463m/s. Plain polyamide, 1040kg/m3 needs 223MPa. Piano C. 4186Hz, 48mm, 402m/s. Plain steel, 7850kg/m3 needs 1268MPa. Plucking or striking the string increases the stress further, in addition to bends at a knot, bridge or nut. For strength, polymers are drawn to wires, which stretches the macromolecules. Hardened high-carbon steel is cold-drawn to harden further. roeslau-draht.de >1720MPa for D=5mm to >2790MPa for D=0.28mm. I mean, wow. ========== Is different steel possible? Austenitic stainless steel exceeds 2000MPa by cold-working. Quality Strings alleges it's abandoned because it cracked more easily when flattened qualitystrings.com but I experienced the opposite with 2000MPa cold-laminated band: notches kill carbon steel band while the 17-7 alloy can be bent flat with a hammer after short tempering around 180°C which improves both the resilience and the proof stress. Tempering uses also to reduce the vibration losses, which I suppose were the real disadvantage. I doubt 17-7 attains 2700MPa but it retains more strength at bents and knots than carbon steel does. Duplex stainless steel behaves much like austenitic. Precipitation hardening austenitic stainless steel hardens by aging after cold-working, easing the effort. The PH 15-7 Mo spring alloy is documented to 1800MPa only but mechanical uses probably didn't exaggerate the cold work enough. Martensitic and ledeburitic stainless steel behaves much like carbon steel. PH 13-8 precipitation-hardens to 1400MPa, so prior cold-drawing may give a good hardness. Maraging steel is seducing. 18Ni12Co5Mo1Ti bring 2400MPa by aging, even at big diameters, with much resilience worth more than brittle 2800MPa. 50% reduction hardens the 18Ni9Co5Mo1Ti from 1900MPa to 2400MPa for instance diccism.unipi.it A violin or a piano afford easily the 50€/kg. Maraging would not rust, even at finger contact, but it can trigger allergies if bare. ========== Other alloys? The cobalt alloy CoCr20Ni16Mo7 similar to maraging steel resists corrosion better than needed. It can trigger allergies if bare. Its strengthening by cold work is documented matthey.ch 1920MPa @60% reduction, 2290MPa @90%, can increase further. Thicker strings of lighter metal may sometimes be better. A violin E string thicker than 1/4thmm would be more comfortable, it might be less prone to hiss and stick better to the bow. Thicker piano bass strings would carry the heavy copper wire in a single layer, which some manufacturers prefer pianopricepoint.com Titanium alloys resist corrosion. Ti6Al4V, Ti6Al6V2Sn, Ti10V2Fe3Al attain by ageing 1100MPa, or the same sound speed as 1950MPa steel, and the same elongation as 2050MPa steel. The equivalent of 2600MPa demands 1470MPa from titanium, hopefully obtained by cold-working. A titanium core of identical mass would be 1.7* stiffer than steel against bending, which has no consequence at a piano bass string. Exotic aluminium alloys attain 810MPa, for instance the RSA-707 made by RSP by rapid solidification and sintering. Same sound speed as 2200MPa steel. Maybe this one, or more common ones like AA7075 (480MPa), attain by cold-working 950MPa, the equivalent of 2600MPa steel. Cold-rolling brings the AA5456, which would resist finger corrosion, to 432MPa at 60% reduction and 487MPa at 80%, so more is possible. High-Pressure Torsion brings AA7075 to 1000MPa and the corrosion-resistent AA5083 to 900MPa nature.com while High-Pressure Sliding, better suited to wires, brings AA7075 to 700MPa researchgate.net they apply to titanium alloys too, but I've seen only the superplastic properties. Metal matrix composites improve the strength-to mass ratio of metals, but they tend to increase the E modulus too, and I suppose they dampen more. ========== Polymers? Polymer ropes of aramide, polyester or polyethylene are lighter than steel at identical resistance cousin-trestec.com exceeding 1000 or 1500m/s sound speed, equivalent to 18 000 MPa steel, but they sound "poc" when plucked. I suppose that braiding, impregnation and cover create damping by friction. Just twisting, possibly twice as in a steel rope, must be better. Polyamide musical strings are monofilament (and don't equal gut sound by far). Polyester and polyethylene get strong by fine extrusion, so quite possibly they must stay multi-filament and keep lossy. How would metal-spun Dyneema sound, properly assembled and stretched, no idea. Ropes thrive to minimise the strain, but musical strings need elastic elongation. That's one simple property where gut outperforms polyamide. The stiffer para-aramide uses to make ropes and meta-aramide fluffy heat-insulating material, but yarn exists too teijinaramid.com Meta-aramide has 1/4th the strength of para-aramide as a fibre. If it retains that factor as a string, it attains 500m/s, and more if twisted rather than braided. So meta-aramide strings can be worth trying. If needing an impregnation, natural rubber is the elastomer with smallest losses. Tennis rackets and other sport goods need strings with similar qualities as music instruments. Meta-aramide may improve them. Marc Schaefer, aka Enthalpy

-

String Instruments

Usual wolf killers seem to use banal elastomers between the string and a metal mass, so they would dampen all frequencies, their relative effect being best felt at the strongest resonance. Schleske's damper is allegedly tuned, and his measured response curves support the claim. He doesn't tell on his website how the damper is built despite having sold several, secretive thing. Just elastomer and a mass is conceivable, but for a stable resonant frequency, I'd prefer an all-metal design which looks easy at 100Hz using small parts in flexural mode. Strings vibrate between the bridge and the holder. They shall not resonate there and get some damping organic wrap from the manufacturer, but they receive movement from the speaking part of the string, over the bridge sitting on the table and the bottom, whose stiffness is limited as they shall vibrate. Some violin workshops even let musicians pay to remove the damping material from the strings there. This changes the sound, and some customers even believe it improves. ========== Erratum to the figures in my message of February 14, 2019 03:09 AM. Was Now ------------------------ 50mm 36mm (drawing) 14mm 22mm (drawing) ------------------------ 20mm 10mm 6.0kN/m 12kN/m 4.4kN/m 10.8kN/m 50mm 36mm 14mm 22mm 4.0kN/m 10.3kN/m ------------------------

-

String Instruments

Luis & Clark manufacture graphite fibre cellos and other instruments luisandclark.com as do some competitors. One amazing record by Scott Crowley 5SRDj9xGAoM on Youtube the détaché starts quickly and neatly, without the noises so common with celli. The musician and the strings matter a lot, but the instrument too. The timbre is extremely clear. This strikes me less at a cello, which I don't play, as wooden instruments too have quite a clear sound. The timbre is also hollow. Most musicians owning a graphite cello comment "useful under temperature contrasts" or "sturdy and easy, nice for students" but "won't give up my wooden instrument". Records of (carbon) graphite fibre violins exist too on Youtube, and they sound just like one expects: badly clear, hollow, with very uneven intensity. No, thanks. From manufacturing videos, the body is just a couple layers of fabric. Then graphite can't compete with wood, as explained here on December 30, 2018. To the very least, it would need a sandwich, for instance with a balsa core, to achieve a decent velocity for flexural waves. Copying a violin's dimensions with an isotropic fabric isn't reasonable neither. Hi StringJunky, thanks for your interest! This works. Several ways exist to kill the wolf tone, with varying selectivity. Some instruments exhibit the instability over 3-4 semitones, which prevents tuning the offending frequency between two semitones. Then you have the worry of unusual tunings (for baroque music, or to play with some historic or detuned instrument), of glissando, portamento... A more selective approach puts an extra mass at the best place on the table. It's also a shift of the offending frequency, but it doesn't affect all the notes. The more common approach puts a damper on the string, between the bridge and the string holder, where the string isn't supposed to resonate. This one reduces the resonance instead of shifting its frequency. But it acts on all notes. Martin Schleske claims to taylor a resonator that dampens only the instrument's offending resonance schleske.de/en his curves support the claim. This would be the best targeted intervention, working for all tunings and leaving intact the rest of the response. The setup I propose is more for research than for an actual instrument. It aims to reproduce my claimed mode split without using a resonance, so if a wolf tone is observed, this will favour my explanation. Or disprove it.