-

Posts

3887 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Everything posted by Enthalpy

-

Do you have a reference to support this? The thread is about Solar panels related with propulsion, if I got it properly, and ISS uses only chemical propulsion at the ISS propulsion module, at Zvezda, and at the Interim Control Module.

-

Are different forms of energy more efficient?

Enthalpy replied to Elite Engineer's topic in Classical Physics

Indicator lights are not made by lasers. -

Your latest quote has gone wrongly, as that message was from EdEarl. 90% power efficiency through magnetic coupling must be possible. Present-day figures are more like 70% for optimized inductive coupling, without a common iron core, but with resonance (and 99.9% for a big transformer, but that's not the same game). What I doubt very seriously is that coupling can remain efficient if the distance exceeds widely one coil diameter. Then it would be a different process, if it really works. Microwaves can make narrow beams over some distance, but their production is at best 70% efficient and their rectification about as bad. Unless reading and seeing more about the demo, I consider it a joke.

-

3D chips have been a subject of discussion for over 30 years. Up to now, they're only a buzzword to describe but more than 2D chips. - Static Ram has been made with P-Mos in polysilicon stacked over bulk monocrystalline silicon N-Mos. - Intel calls 3D its Mos with vertical channel. Everything else in the process is flat. No stacking, especially. - Some assembling manufacturer stacked complete 2D chips, especially Dram, to increase the packing density and reduce connection length. Not really thrilling, is it? One would have expected as many transistors stacked as there are side-by-side, to integrate quintillions of them - or to reduce the on-chip wiring length and eventually break the propagation delays that prevent for a decade chips from improving. Building chips atom by atom would take a prohibitive time up to now, even for the few atomic layers that are active on a cm2 chip. More and more people think at it, so a breakthrough may come in a not so near future. ----- At ablative re-entry heat shields, carbon is interesting because upon deterioration, it makes an opaque gas or dust that protects the craft from heat radiated by the shock wave. It's also nice as it takes much heat to evaporate. Both advantages require the ablative material to evolve as a gas and to transmit little heat, which favours a carbon-rich organic material over carbon, and rather a fluffy over a compact one - the latter being not mandatory if a deeper layer insulates the craft. This makes phenolic resin a good candidate for instance, as it's sounder and easier to use than tar. Re-usable protection is a different approach, taken only to re-enter from low-Earth-orbit up to now, for which carbon-carbon is one good material.

-

It is being used in advanced space probes to achieve propulsion performance unattainable by chemical reactions. The limit is the instantaneous power, no the energy, so it's used at some phases of the trip only.

-

Wiki sometimes contains plain rubbish, which spreads to the Web widely and quickly. I consider the anaerobic detonation of cyclopropane to be such a rubbish from Wiki: the explanations and mitigation methods are not believable, no single independent source (MSDS...) tells of brutal decomposition, and cyclopropane has been used for decades in fridges. Though, the article has been translated as is and copied everywhere. Which does not change my admiration and thankfulness for Wiki.

-

Blackbody radiation and ultraviolet catastrophe?

Enthalpy replied to Stratus's topic in Quantum Theory

Not ocean waves. For sound and light, yes if the medium is non-dispersive. -

New era for astronomic observation... IceCube has made its first observations, with 28 neutrinos of known direction and energy. http://www.bbc.co.uk/news/science-environment-22540352 http://en.wikipedia.org/wiki/IceCube two of the first papers are on arXiv: http://arxiv.org/abs/0905.2253 http://arxiv.org/abs/0902.2460

- 1 reply

-

1

-

Questions about molten rock in space.

Enthalpy replied to too-open-minded's topic in Astronomy and Cosmology

Our Sun makes the difference between 288K at Earth's surface and very cold. The rest, from 288K to 3000K at the center (value still debated), results from internal heat. So the 288K make little difference, despite Sunlight is much stronger. What is the internal heat? Not completely known yet. 2/3 radioactivity and 1/3 accretion heat (the gravitation/kinetic energy of materials that made the planet)? More recently they said 1/3 and 2/3 instead. Meanwhile the innermost core is said to be iron+nickel that solidify due to the pressure, and this slow process releases some heat. We may know more some day through neutrino telescopes that would "map" (very roughly) the position of radioactive materials in our planet. Have other planets the same source(s) of heat? Unclear at Jupiter for instance. It radiates more heat than it receives Sunlight, which needs more efficient internal heat than Earth. Current interpretations involve the condensation and solidification of gases. -

Only the third link describes a superconductor, that one at 30K.

-

Since the last time you checked that, computers have gotten rewritable memory to store the Bios. Same for all hardware with a microcode, for instance a disk host or a graphics card can receive an update. One excellent reason for it is that true Rom chips are not available any more.

-

"Wireless power transmission" uses to mean by magnetic coupling, which - Works at short distance only (but possibly at traffic lights, with loops embedded in the lane) - Has a limited efficiency, often <70%, but might be improved. Though, 98% would surprise me. "Quantum efficiency" is normally used in opto devices and would be useless for magnetic coupling. Opto transmitter have a QE lower than 98%; opto receiver can have 98 QE, but the output electrons are available under a lower voltage than the photon energy, which means an energy efficiency seriously lower.

-

Would your web search dexterity indicate us a description of the material you mention, superconductive at or near room temperature? At whatever pressure.

-

Water splatter is very important in cooling towers for power stations. This very mechanism makes the intimate contact between water and air. But whether this data has been published is doubtful. The cooling tower is a very difficult part of a power station, its optimisation mean a bunch of bucks.

-

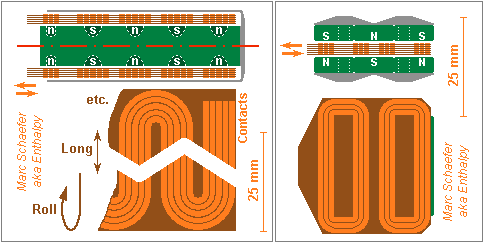

The following actuators with mobile coil are smaller and lighter. The battery is but heavier as the actuators draw more power for a constant force. The cylindric actuator, left side of the sketch, has a single D=10mm L=50mm magnet to create all 4.5 poles: easier to assemble. CyMagnetics' N38 material (915kA/m and µ=1.06) creates 0.55T at the coils' 13.5mm mean diameter - the induction dilutes from the 4mm long poles, but the 8mm long coils catch it. Iron poles were useless for this induction. Constant 1N takes 100mW. The actuator fits in D=18mm, weighs 70g, with 23g for the mobile part. ---------- A flexible printed circuit makes the coils set. 50µm patterned copper over 25µm of polyimide or polyester film use well the volume. The film is rolled to make the cylindre without keeping a coil former; adhesive tape, liquid glue, or pre-molten or re-molten glue, makes a stiff solid part. 33 turns would bring 2.5mm thickness (with 0.5+0.5mm clearance) and a few tracks connected externally adapt to the supply voltage, so this part of the sketch is not to scale. A flexible circuit is also a reliable way to connect the moving part. If the tracks keep their respective positions over the pole sequence, they can be powered individually, say to use current only in the tracks that receive a strong induction at a given coil displacement. The stroke can even exceed a pole spacing if the current is properly inverted - better than a voice coil motor, this is now a multiphase linear motor, smaller and of more flexible design. The tracks must cross an other to keep the relative positions. A double layer flexible circuit does it. Its lower and upper copper can be already coated or get a separate insulation layer: an extra film, the adhesive tape, or a fabric soaked with liquid, pre-molten or re-molten glue. ---------- A coil or coils set made of flexible printed circuit has more uses, for instance at loudspeakers, other voice coil motors and generators, hard disk drives' arm actuator, and also at rotative actuators, motors and generators, including bell-shaped rotors, other low-inertia motors, and fast-rotating motors. On the right side of the sketch, the flat actuator resembles a hard disk drive's arm motor, but has three pole pairs for convenient shape, and the coils translate, which seems better than rotate here. The flat design is more adaptable. The example uses 4mm thick N38 material, where 2*3 magnets give their 25mm width and cumulate three 10mm lengths to span three poles of 6mm, 12mm and 6mm length separated by 3mm leak stoppers. This time the coil bars are 4mm wide, narrower than the magnetic poles. The lower half-stator mirrors the upper, and they achieve together 0.8T, so the actuator uses 71mW for 1N, weighs 73g with 12g for the mobile part, and is thin and short. Copper wire could make the coils set, for instance coated with glue, or included in a thermoplastic injection like in hard disk drives... But a thin printed circuit makes the solid coils pair easily and fits small production series. Stacks of spiral-patterned circuits (sketch simplified) would be hard to connect; a double-sided circuit instead can be folded to make the connected stack - or better, winded flat to make the stack, possibly keeping some bending radius at the edges outside the stator. The tracks can be locally wider. The refinements with tracks powered individually apply here as well. Marc Schaefer, aka Enthalpy

-

Questions and thought experiment about metal vacuum deposition

Enthalpy replied to keegreil's topic in Amateur Science

When we deposited aluminium on silicon wafers we needed a secondary vacuum seriously better than 1e-6 torr. Was it 1-e9? I've forgotten. Aluminium will get oxygen and hydrogen from the chamber, but not necessarily hydrogen, argon, carbon monoxide (once aluminium has converted the dioxide). Whatever your means to create the deep vacuum, it will fight against the leaks from the primary pump, and I doubt metal evaporation has the necessary throughput. Titanium evaporation is used for that purpose, but only after a secondary pump has already done its mission. An oil diffusion pump isn't that exotic... It's a very simple pump, reliable, easy to operate, efficient. My suggestions would be: - Find a university with a microelectronics lab, make some deal to get your mirrors coated. Like: invite them to observation nights. - Buy a used aluminium evaporation machine. It would be third-hand nowadays, probably dirt-cheap. - Candy wrapping still uses aluminium evaporation on polyester films, in huge machines. - Do not try to assemble the machine by yourself. Evaporation is usually done by an electron beam so the crucible remains luke-warm an doesn't pollute the aluminium - nothing simple to my eyes. - Check the price of aluminium, I've doubts on that one. A <100nm layer that resists corrosion must be pure. - Try wet methods to deposit gold. ======================== Seen evaporation targets of aluminium on eBay, item #390317323315 there, they want 330 usd for 1 pound, quality is not specified. For mechanical parts, you get alloy 99,8% pure, but I doubt it suffices for a mirror's ultra-thin layer. Purer exists to make electrolytic capacitors, but where to get it? For microelectronics, we had <<1ppm impurities. -

I need to ask a few questions, please help??

Enthalpy replied to Ein_Wannabe's topic in Other Sciences

I know no material that stays ferromagnetic beyond its melting point. But would it be possible? Unclear to me. Liquids show some order, but only at a small scale, and this scale reduces quickly as temperature rises a little over the melting point. Liquid crystals keep order to a longer range and over a wider temperature span. This might open the possibility, maybe perhaps. It seems that nobody has found a ferromagnetic liquid up to now, since technology reverts to ferrofluids instead, despite their drawbacks. A ferromagnetic liquid would be very nice to build fridges. -

A mock turtle is what mock turtle soup is made of. http://en.wikipedia.org/wiki/Alice%27s_Adventures_in_Wonderland And hardware abstraction is what layers are made of.

-

You can get flammable gas and liquids by pyrolysis of old tyres from instance. Not extremely surprising since tyres themselves burn easily. But it would be an introduction to a transformation many people would like to do (I mean, do properly, with no ugly leftovers). Same with polyethylene and polypropylene garbage. Pyrolysis gives you flammable gas. Many studies try to make this useful. Methanise grass and other vegetals in a bio-reactor. This looks more magic, since wet grass doesn't burn usually. Show that metals burn in air if finely divided. Be careful, some are brutal. Burn ordinary sugar (sucrose) in air using a catalyst. Burn oil (vegetal, Diesel...) with a wick. Or more impressive, with an injector. Put wax alight without a wick, by heating it. Caution: avoid moisture, and do NOT extinguish it with water; cap it instead.

-

Regrettably: - I see no firm relationship between superconductivity and a circuit board - Nor with EM broadcast, or a loose one at best - I ignore what a holographic circuit board might be - Googling "Holographic Circuit Board" answers nonsense and links to crank forums. So could you check whether your sources make sense, and maybe give us more details (sensible ones)? Until then, I answer the question you don't want, and with "NO".

-

Questions and thought experiment about metal vacuum deposition

Enthalpy replied to keegreil's topic in Amateur Science

Silver is not very durable, a reason why astronomers prefer aluminium or gold. Is there a solution that deposits gold without using cyanides? Few gold salts are soluble. -

Could the apparatus help divers? Visibility is often poor where they need to operate, and sound propagates well underwater. Divers may (or not) prefer a tactile information to a visual display. For a limited range like 20m, high frequencies are possible. Echoes are a lesser worry in water, but should still be processed away. Marc Schaefer, aka Enthalpy

-

Some people suggested me to use ultrasound instead of a laser. This would have drawbacks: Sound takes 0.1s to reflect from 17m distance, so the user could not scan his environment quickly enough with his own movements; The angular resolution is bad. At 340kHz (already much for air propagation), a 50mm source, reflector or lens still makes the main lobe 2*0.24m wide at 10m distance. Acoustics is plagued by parasitic reflections. Some signal processing methods can alleviate them, nothing easy nor perfect. so light is generally better. If using sound, say in environments of bad visibility (fire brigade), scanning can be fast enough: Send a ping in all directions, listen to the echoes from all directions simultaneously, as Sonar do it for the same reason; Reconstruct the echoes from individual directions by signal processing, called "aperture synthesis", as Sonar and Radar do it; Store the information about the environment, give it to the user one at a time, just in the direction he designates; For that, the user may have a gyrometer or an other orientation sensor, for instance at his hand, and for example a tactile actuator in a glove. Marc Schaefer, aka Enthalpy

-

I don't quite understand the difficulty. Bikes run already at 360km/h and use gasoline for that, in a piston engine. Have a propeller if no wheel is available, or a turbofan to look more S-F. Consume electricity if you wish, from a battery or a hydrogen fuel cell - both easy with existing technology. I nearly wrote "360km/s", and this speed would need exotic engines and fuels. Not 360km/h.