annlee

-

Posts

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by annlee

-

-

Soda lime is fairly cheap and is so old it can't be patented these days.

But the real question I'd still like you to answer is why bother?

very interesting John, now I have something to research

I want to absorb the CO2 of steam boiler for 48 hours, which rate % of absortion do you expect? and how much kgs of soda lime will be needed? how to recycle soda lime?

btw why do you like signatures THAT much?

thanks0

thanks0 -

There's a few bigger problems.

If you cool wet smoky air to about 1C most, but not all, of the water will condense.

That water will dissolve some components of the mixture- notably CO2.

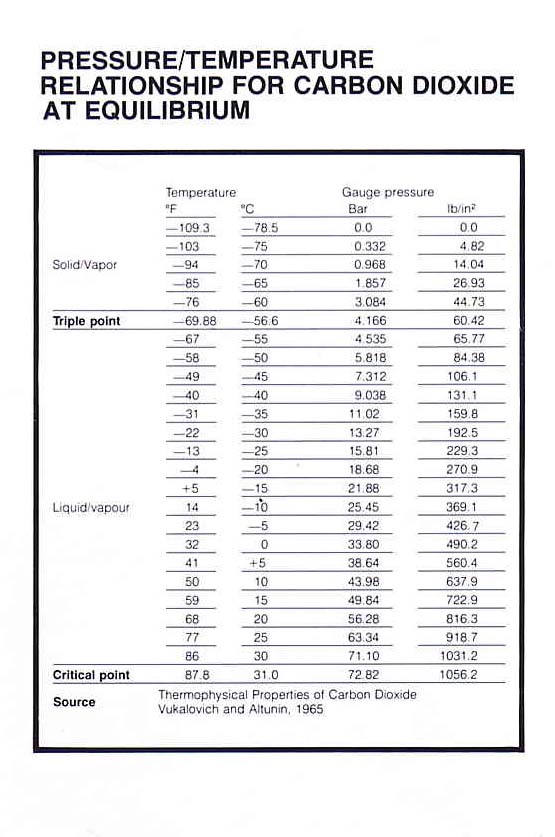

Also, if you cool air to -80 C none of the CO2 will condense- the temperature of dry ice- about -80C is the temperature where solid CO2 is in equilibrium with the gas at a pressure of 1 atmosphere.

But in ordinary air the partial pressure of CO2 is only about a three thousandth of an atmosphere.

Gas sampling is difficult (I spent about 20 years working mainly in that field).

What are you actually trying to find out.

Dear John,

(for now) I need to find a method to separate CO2 from pollutant air,

I have found many expensive, advanced and (ofc patented!) ways: membranes, materials, laser, CaO... not feasible

Having a tank at 5ºC and 40 bar to keep CO2 could be feasible but I think it may need a lot of energy, if this energy is stop then the tank may expode since CO2 is turn into gas again

In other words, what I need is a cheap and feasible method (not patented) for taking CO2 from pollutant air

0 -

there is another issue, the storage in liquid state, I may need a sensor into the very high pressure tank to cool it up to keep it liquid:

0

0 -

The short answer is yes it is possible using fractional distillation.

Should probably look into gas analysis instead.

You can convert a gas into a liquid via typically cooling and pressurization, but could easily get expensive depending on the gasses involved. What you'll want to do is look at the phase diagrams for the gasses you expect to see and work from there to figure out feasibility.

Thanks guys, this is what I plan to do:

- 1st device makes condensation of pollutant air cooling up to 1ºC aprox, so H2O is liquified and this is expulsed out of the system (not needed for analysis) (consider aprox. 1,5grs of air is present per 1gr of gasoline after combustion)

- 2nd device takes the resulting gas without water and cool it up to -80ºC (point for CO2) and this liquid is stored

the rest of gases are expulsed since this study will consider only CO2 (for now)

There are many aspects to point out: pumps, filters, other gases affected by this, devices, continuously air issues, pressure...

but, briefly, does it make sense guys? thanks in advance

1 -

hi there, name's Ann, want to learn about how to make pollutant gas into liquid

cheers!

0 -

hi there I am new!

I am doing an experiment to obtain pure liquid from smoke gas from: steam boiler vs car exhaust without gass loss, then will send to a lab to analyze its CO2 and other parameters, questions:

- is this liquefaction experiment possible? (do I need to cool-up smoke before and how? is this smoke liquified-able...)

- which industrial device(s) to use? (cheap and small if possible, consider must absorb smoke continuously...)

Thanks in advance

0

0

How to obtain pure liquefied gas from pollutant smoke?

in Classical Physics

Posted · Edited by annlee

thanks a lot! the amine stuff seems too complex and expensive for this home experiment

seems if you have (let's say) smoke with 15% of CO2 from a boiler of 70kgs of combustible (10,5 kgs of CO2 in total), being expulsed in 24 hours, (this is 0,4375kg/hour = 7,3grs/minute), then I may need at least 3 times that weight on soda lime (31,5 kgs) to absorb it, isn't it too bad rate of absortion?

regarding soda lime recycling, do you think it would be the same process than for glasses but considering it has CO2 should differ I guess

why are you doing this? I am doing a small research to find "feasible methods for separating CO2", this is a topic I have been assigned in my class